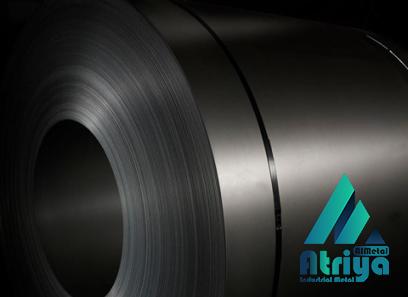

Choosing the Right Option for Your Business In the world of steel, there are two competing methods of production that offer different qualities and applications: cold rolled steel and hot rolled steel. Understanding the characteristics and benefits of each can help businesses make informed decisions when it comes to selecting the right steel product for their needs. What is Cold Rolled Steel? Cold rolled steel is derived from hot rolled steel, but it undergoes additional processing to improve its surface finish and dimensional accuracy. The process involves passing the steel through rollers at room temperature, which compress and shape it. This results in a smooth, polished surface and tighter tolerances. Advantages of Cold Rolled Steel: 1. Superior Surface Finish: Cold rolled steel exhibits a smoother and finer finish compared to hot rolled steel.

.

This makes it well-suited for applications where appearance matters, such as exposed architectural elements, appliances, and automotive components. 2. Precise Dimensions: Cold rolled steel is known for its dimensional accuracy. The controlled compression during the rolling process ensures consistent thickness and width, making it ideal for products with tight tolerances. 3. Increased Strength: The cold rolling process induces strain hardening in the steel, giving it improved strength. This makes cold rolled steel suitable for applications where strength is key, such as construction, machinery, and automotive manufacturing. What is Hot Rolled Steel? Hot rolled steel, as the name suggests, is produced through a process that involves heating the steel above its recrystallization temperature and passing it through rolls. This results in a product with a rough surface finish and looser tolerances compared to cold rolled steel.

This makes it well-suited for applications where appearance matters, such as exposed architectural elements, appliances, and automotive components. 2. Precise Dimensions: Cold rolled steel is known for its dimensional accuracy. The controlled compression during the rolling process ensures consistent thickness and width, making it ideal for products with tight tolerances. 3. Increased Strength: The cold rolling process induces strain hardening in the steel, giving it improved strength. This makes cold rolled steel suitable for applications where strength is key, such as construction, machinery, and automotive manufacturing. What is Hot Rolled Steel? Hot rolled steel, as the name suggests, is produced through a process that involves heating the steel above its recrystallization temperature and passing it through rolls. This results in a product with a rough surface finish and looser tolerances compared to cold rolled steel.

..

Advantages of Hot Rolled Steel: 1. Cost-effective Production: Hot rolled steel is generally more cost-effective to produce than cold rolled steel due to the simpler manufacturing process. This makes it a popular choice for large-scale projects and applications where cost is a primary concern. 2. Greater Ductility: Hot rolled steel has higher ductility than cold rolled steel, meaning it can be formed and shaped more easily. This makes it suitable for applications that require extensive bending, such as structural steel elements, pipes, and tubing. 3. Increased Workability: Hot rolled steel is less brittle than cold rolled steel, allowing for easier welding, machining, and fabrication. This makes it preferable for projects that involve extensive further processing.

Advantages of Hot Rolled Steel: 1. Cost-effective Production: Hot rolled steel is generally more cost-effective to produce than cold rolled steel due to the simpler manufacturing process. This makes it a popular choice for large-scale projects and applications where cost is a primary concern. 2. Greater Ductility: Hot rolled steel has higher ductility than cold rolled steel, meaning it can be formed and shaped more easily. This makes it suitable for applications that require extensive bending, such as structural steel elements, pipes, and tubing. 3. Increased Workability: Hot rolled steel is less brittle than cold rolled steel, allowing for easier welding, machining, and fabrication. This makes it preferable for projects that involve extensive further processing.

…

Choosing the Right Steel for Your Business: When deciding between cold rolled steel and hot rolled steel, businesses should consider their specific requirements and priorities. If appearance, dimensional accuracy, and strength are vital, cold rolled steel may be the better option. On the other hand, if cost-effectiveness, ductility, and workability are paramount, hot rolled steel might be the more suitable choice. It is important to consult with steel suppliers or industry experts to fully understand the characteristics, applications, and limitations of each steel type. By making an informed decision, businesses can ensure they select the most appropriate steel product to meet their needs and achieve optimal results in their operations.

Choosing the Right Steel for Your Business: When deciding between cold rolled steel and hot rolled steel, businesses should consider their specific requirements and priorities. If appearance, dimensional accuracy, and strength are vital, cold rolled steel may be the better option. On the other hand, if cost-effectiveness, ductility, and workability are paramount, hot rolled steel might be the more suitable choice. It is important to consult with steel suppliers or industry experts to fully understand the characteristics, applications, and limitations of each steel type. By making an informed decision, businesses can ensure they select the most appropriate steel product to meet their needs and achieve optimal results in their operations.

Your comment submitted.