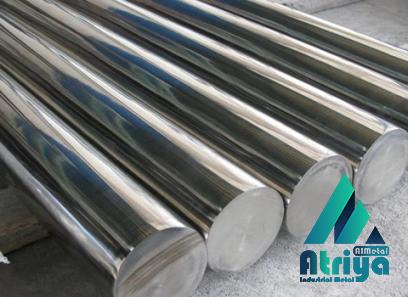

Aluminum is an incredibly versatile and widely used metal in various industries. Among its many applications, aluminum bars are an essential component in the manufacturing and construction sectors. These bars provide a durable and lightweight alternative to their steel counterparts, making them a preferred choice for a range of applications. Aluminum bars are made through a process called extrusion. This involves forcing heated aluminum through a die to create a specific shape. The resulting bars have a uniform cross-section and can be produced in different sizes and lengths to suit various requirements. One of the primary advantages of aluminum bars is their low density. Aluminum has a density of roughly one-third of steel, making aluminum bars significantly lighter.

.

This characteristic makes them ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries. The lightweight nature of aluminum bars also simplifies transportation and installation processes, reducing overall costs. Another important feature of aluminum bars is their corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to air. This oxide layer prevents further corrosion, making aluminum bars highly resistant to rust and weathering. This resistance to corrosion makes them suitable for outdoor applications, such as in construction projects or marine environments. Despite their lightweight nature, aluminum bars boast impressive strength properties.

This characteristic makes them ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries. The lightweight nature of aluminum bars also simplifies transportation and installation processes, reducing overall costs. Another important feature of aluminum bars is their corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to air. This oxide layer prevents further corrosion, making aluminum bars highly resistant to rust and weathering. This resistance to corrosion makes them suitable for outdoor applications, such as in construction projects or marine environments. Despite their lightweight nature, aluminum bars boast impressive strength properties.

..

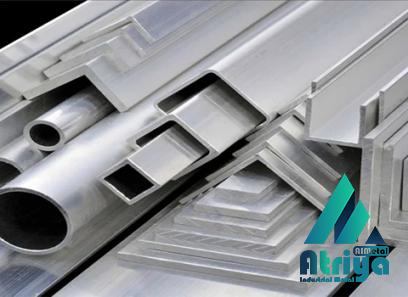

The alloying process used in their production enhances their strength, allowing them to withstand heavy loads and structural stresses. This strength is particularly valuable in applications where both durability and weight reduction are crucial, such as in the construction of bridges or high-rise buildings. In addition to their strength, aluminum bars also offer excellent thermal and electrical conductivity. These properties make them suitable for applications in the electrical and thermal management industries. Aluminum bars are commonly used in the production of heat sinks and electrical conductors, where efficient heat dissipation or electrical conductivity is essential. Aluminum bars are also widely used in the manufacturing of machinery and equipment.

The alloying process used in their production enhances their strength, allowing them to withstand heavy loads and structural stresses. This strength is particularly valuable in applications where both durability and weight reduction are crucial, such as in the construction of bridges or high-rise buildings. In addition to their strength, aluminum bars also offer excellent thermal and electrical conductivity. These properties make them suitable for applications in the electrical and thermal management industries. Aluminum bars are commonly used in the production of heat sinks and electrical conductors, where efficient heat dissipation or electrical conductivity is essential. Aluminum bars are also widely used in the manufacturing of machinery and equipment.

…

Their lightweight nature and high strength-to-weight ratio make them an excellent choice for the construction of machine frames, tooling components, and industrial structures. The versatility of aluminum bars allows them to be easily machined, welded, and formed into complex shapes, providing manufacturers with endless design possibilities. In conclusion, aluminum bars are a vital component in various industries due to their lightweight, corrosion resistance, strength, and excellent thermal and electrical conductivity. Their versatility, coupled with their cost-effectiveness, makes them a popular choice for a wide range of applications. The use of aluminum bars adds value to products and projects by offering durability, efficiency, and reduced maintenance costs. As industries continue to innovate and strive for enhanced performance, the demand for aluminum bars is likely to remain strong.

Their lightweight nature and high strength-to-weight ratio make them an excellent choice for the construction of machine frames, tooling components, and industrial structures. The versatility of aluminum bars allows them to be easily machined, welded, and formed into complex shapes, providing manufacturers with endless design possibilities. In conclusion, aluminum bars are a vital component in various industries due to their lightweight, corrosion resistance, strength, and excellent thermal and electrical conductivity. Their versatility, coupled with their cost-effectiveness, makes them a popular choice for a wide range of applications. The use of aluminum bars adds value to products and projects by offering durability, efficiency, and reduced maintenance costs. As industries continue to innovate and strive for enhanced performance, the demand for aluminum bars is likely to remain strong.

Your comment submitted.