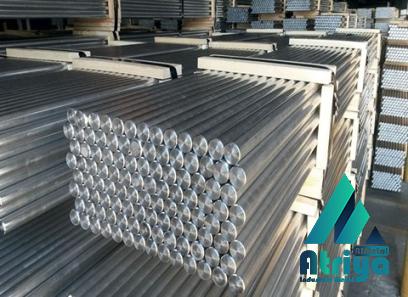

Mill scale, a flaky surface material that forms on the outer surface of rebar during the fabrication process, is a common occurrence in the construction industry. While it may seem like a minor cosmetic issue, mill scale on rebar can have significant consequences if not properly addressed. In this article, we will explore what mill scale is, its impact on rebar, and the steps that can be taken to prevent and remove it. Mill scale is the dark, oxide layer that forms on the surface of steel when it is heated and exposed to air during the manufacturing process. It is composed mainly of iron oxide and can vary in thickness and appearance. When rebar is produced, it is often hot-rolled and left to cool, allowing mill scale to develop. This scale can range from a thin, flaky layer to a thicker, more adherent coating. While mill scale on rebar may not seem like a major concern, it can have several negative effects.

.

Firstly, it affects the bond between the rebar and the surrounding concrete. Mill scale prevents proper adhesion between the rebar and the concrete, reducing the strength and durability of the structure. This can compromise the structural integrity of the construction, posing significant safety risks. Additionally, mill scale can hinder the proper formation of a protective oxide layer on the rebar’s surface. This oxide layer acts as a barrier, preventing corrosion and extending the lifespan of the rebar. If mill scale is not removed, it can create a pathway for moisture and corrosive elements to penetrate the rebar, leading to premature corrosion and deterioration.

Firstly, it affects the bond between the rebar and the surrounding concrete. Mill scale prevents proper adhesion between the rebar and the concrete, reducing the strength and durability of the structure. This can compromise the structural integrity of the construction, posing significant safety risks. Additionally, mill scale can hinder the proper formation of a protective oxide layer on the rebar’s surface. This oxide layer acts as a barrier, preventing corrosion and extending the lifespan of the rebar. If mill scale is not removed, it can create a pathway for moisture and corrosive elements to penetrate the rebar, leading to premature corrosion and deterioration.

..

To prevent the negative effects of mill scale on rebar, several steps can be taken. Firstly, it is crucial to ensure that the rebar used in construction is properly cleaned and free from mill scale. Manufacturers should implement quality control measures to remove mill scale during the production process. Regular inspections should also be carried out on rebar to identify any signs of mill scale and take appropriate measures to address it. If mill scale is present on rebar, it is essential to remove it before using the rebar in construction. Mechanical methods, such as wire brushing or sandblasting, can be employed to remove the scale effectively. Chemical methods, such as using specially formulated mill scale removers, can also be utilized.

To prevent the negative effects of mill scale on rebar, several steps can be taken. Firstly, it is crucial to ensure that the rebar used in construction is properly cleaned and free from mill scale. Manufacturers should implement quality control measures to remove mill scale during the production process. Regular inspections should also be carried out on rebar to identify any signs of mill scale and take appropriate measures to address it. If mill scale is present on rebar, it is essential to remove it before using the rebar in construction. Mechanical methods, such as wire brushing or sandblasting, can be employed to remove the scale effectively. Chemical methods, such as using specially formulated mill scale removers, can also be utilized.

…

It is essential to follow proper safety protocols when using chemical removers and to ensure thorough rinsing of the rebar to eliminate any residues. In conclusion, mill scale on rebar may appear as a minor issue, but it can have significant consequences on the structural integrity and durability of a construction project. It is crucial for manufacturers and construction professionals to be aware of the potential risks associated with mill scale and take appropriate measures to prevent and remove it. By ensuring the cleanliness of rebar and implementing proper cleaning methods, the negative effects of mill scale can be mitigated, leading to safer and more sustainable constructions.

It is essential to follow proper safety protocols when using chemical removers and to ensure thorough rinsing of the rebar to eliminate any residues. In conclusion, mill scale on rebar may appear as a minor issue, but it can have significant consequences on the structural integrity and durability of a construction project. It is crucial for manufacturers and construction professionals to be aware of the potential risks associated with mill scale and take appropriate measures to prevent and remove it. By ensuring the cleanliness of rebar and implementing proper cleaning methods, the negative effects of mill scale can be mitigated, leading to safer and more sustainable constructions.

Your comment submitted.