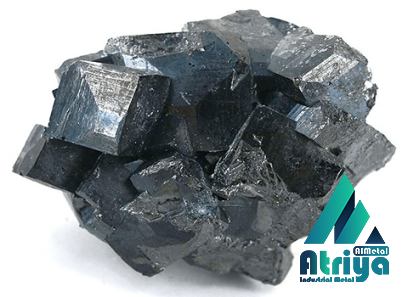

Understanding the Differences When it comes to the production of iron, the two commonly used processes are the direct reduction method, which produces sponge iron, and the traditional blast furnace method, which produces pig iron. Both of these materials have their own unique properties and applications in various industries. Understanding the differences between sponge iron and pig iron is crucial for making informed decisions in terms of material selection. To begin with, let’s delve into the process of producing sponge iron. This method utilizes iron ore as the primary raw material and involves the removal of oxygen from the ore to obtain a highly pure form of iron. In the direct reduction method, iron ore is subjected to a reduction reaction at high temperatures, typically in the range of 800 to 1050 degrees Celsius. This reaction is known as a direct reduction, as it bypasses the traditional blast furnace process. The result of this reaction is a metallic iron product with a sponge-like structure, hence the name “sponge iron.” On the other hand, pig iron is the product of the blast furnace method, which has been used for centuries.

.

This process involves the smelting of iron ore in a blast furnace, along with the addition of coke and limestone as auxiliary agents. The intense heat inside the furnace causes the iron ore to melt, resulting in the production of pig iron. Pig iron is characterized by its high carbon content, typically ranging from 3 to 4.5%. This high carbon content makes pig iron brittle and unsuitable for many applications without further refining. One of the key differences between sponge iron and pig iron lies in their carbon content. Sponge iron typically has a lower carbon content compared to pig iron, making it more pliable and easy to work with. This lower carbon content also makes sponge iron suitable for further processing and refining into steel. Pig iron, on the other hand, requires additional steps such as conversion into cast iron or steel to make it usable in various industries. Another significant difference is the chemical composition.

This process involves the smelting of iron ore in a blast furnace, along with the addition of coke and limestone as auxiliary agents. The intense heat inside the furnace causes the iron ore to melt, resulting in the production of pig iron. Pig iron is characterized by its high carbon content, typically ranging from 3 to 4.5%. This high carbon content makes pig iron brittle and unsuitable for many applications without further refining. One of the key differences between sponge iron and pig iron lies in their carbon content. Sponge iron typically has a lower carbon content compared to pig iron, making it more pliable and easy to work with. This lower carbon content also makes sponge iron suitable for further processing and refining into steel. Pig iron, on the other hand, requires additional steps such as conversion into cast iron or steel to make it usable in various industries. Another significant difference is the chemical composition.

..

Apart from carbon, pig iron may also contain impurities such as sulfur, silicon, and phosphorus, depending on the quality of the iron ore and the blast furnace process. In contrast, sponge iron is purer and has a more consistent chemical composition, making it ideal for applications where precise compositions are required, such as in the production of specific types of steel. In terms of applications, sponge iron is widely used as a raw material in the steel industry. It can be further processed and blended with other metals to create different types of steel, catering to various industrial needs. Additionally, sponge iron can also be utilized in the manufacturing of automotive parts, machinery, and tools, thanks to its malleability and ease of shaping. Pig iron, on the other hand, finds application primarily in the casting industry. Its high carbon content makes it ideal for casting molten iron into various shapes, such as pipes, fittings, and engine blocks.

Apart from carbon, pig iron may also contain impurities such as sulfur, silicon, and phosphorus, depending on the quality of the iron ore and the blast furnace process. In contrast, sponge iron is purer and has a more consistent chemical composition, making it ideal for applications where precise compositions are required, such as in the production of specific types of steel. In terms of applications, sponge iron is widely used as a raw material in the steel industry. It can be further processed and blended with other metals to create different types of steel, catering to various industrial needs. Additionally, sponge iron can also be utilized in the manufacturing of automotive parts, machinery, and tools, thanks to its malleability and ease of shaping. Pig iron, on the other hand, finds application primarily in the casting industry. Its high carbon content makes it ideal for casting molten iron into various shapes, such as pipes, fittings, and engine blocks.

…

Pig iron is also used as a basic ingredient in the production of cast iron, which is further processed to manufacture cookware, pipes, and other iron-based products. In conclusion, understanding the differences between sponge iron and pig iron is essential for making informed decisions regarding material selection. Sponge iron, produced through the direct reduction process, is characterized by its lower carbon content and pure composition, making it suitable for further processing into steel. Pig iron, on the other hand, is the product of the blast furnace method and is characterized by its high carbon content, making it ideal for casting applications. Both materials have their unique advantages and applications, catering to different industries and manufacturing processes.

Pig iron is also used as a basic ingredient in the production of cast iron, which is further processed to manufacture cookware, pipes, and other iron-based products. In conclusion, understanding the differences between sponge iron and pig iron is essential for making informed decisions regarding material selection. Sponge iron, produced through the direct reduction process, is characterized by its lower carbon content and pure composition, making it suitable for further processing into steel. Pig iron, on the other hand, is the product of the blast furnace method and is characterized by its high carbon content, making it ideal for casting applications. Both materials have their unique advantages and applications, catering to different industries and manufacturing processes.

Your comment submitted.