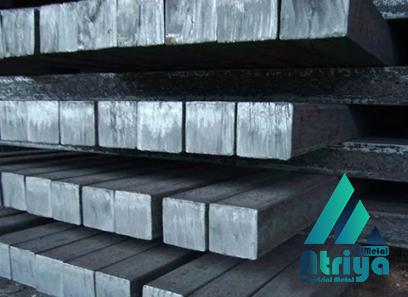

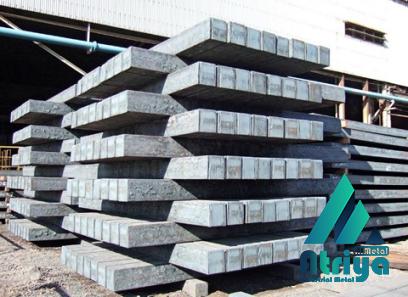

Choosing the Right Material for Your Business Needs When it comes to selecting the right material for various applications, cast iron and steel stand out as two popular choices. Both materials have their own unique characteristics and advantages, making them suitable for a wide range of industries. In this article, we will explore the differences between cast iron and steel, helping businesses make informed decisions when it comes to material selection. 1. Composition and Manufacturing Process: Cast iron is a brittle metal primarily composed of iron, carbon, and silicon. It is made by melting iron and adding a high carbon content, typically between 2% and 4%. The molten iron is then poured into molds to shape it into the desired product. The high carbon content gives cast iron its strength and hardness. Steel, on the other hand, is an alloy made mainly of iron and carbon, with other elements such as manganese, chromium, or nickel added to enhance certain properties. The manufacturing process involves melting iron and adding specific amounts of carbon and other elements, followed by casting, rolling, or forging to shape the steel.

.

2. Strength and Durability: Steel is widely known for its strength and durability. It offers excellent tensile strength, making it suitable for applications that require toughness and resistance to deformation. Steel is also highly resistant to wear and corrosion, which makes it an ideal choice for structural applications, machinery components, and tools. Cast iron, although not as strong as steel, is known for its exceptional compressive strength. It is highly resistant to wear and can withstand heavy loads, making it ideal for applications that require high resistance to impact and compression. Cast iron is commonly used for engine blocks, pipes, cookware, and ornamental structures.

2. Strength and Durability: Steel is widely known for its strength and durability. It offers excellent tensile strength, making it suitable for applications that require toughness and resistance to deformation. Steel is also highly resistant to wear and corrosion, which makes it an ideal choice for structural applications, machinery components, and tools. Cast iron, although not as strong as steel, is known for its exceptional compressive strength. It is highly resistant to wear and can withstand heavy loads, making it ideal for applications that require high resistance to impact and compression. Cast iron is commonly used for engine blocks, pipes, cookware, and ornamental structures.

..

3. Heat Conductivity and Retention: Cast iron exhibits excellent heat retention properties. It heats up slowly and distributes heat evenly, making it ideal for applications where uniform heating is required. Cast iron cookware, for example, is often preferred by chefs for its ability to retain heat and provide consistent cooking results. Steel, on the other hand, has comparatively lower heat retention properties. It heats up and cools down relatively quickly, making it suitable for applications such as heat exchangers, cooktops, and radiant heating systems where rapid heat transfer is desired. 4. Machinability: Steel is generally easier to machine than cast iron. Its composition allows for better chip control and lower cutting forces, making it more convenient for shaping, drilling, and cutting operations.

3. Heat Conductivity and Retention: Cast iron exhibits excellent heat retention properties. It heats up slowly and distributes heat evenly, making it ideal for applications where uniform heating is required. Cast iron cookware, for example, is often preferred by chefs for its ability to retain heat and provide consistent cooking results. Steel, on the other hand, has comparatively lower heat retention properties. It heats up and cools down relatively quickly, making it suitable for applications such as heat exchangers, cooktops, and radiant heating systems where rapid heat transfer is desired. 4. Machinability: Steel is generally easier to machine than cast iron. Its composition allows for better chip control and lower cutting forces, making it more convenient for shaping, drilling, and cutting operations.

…

Steel’s machinability makes it a popular choice in industries such as automotive, aerospace, and manufacturing, where precise machining is required. Cast iron, on the other hand, can be more challenging to machine due to its brittle nature. It is prone to producing vibrations during cutting operations, which can lead to tool wear and reduced surface finish. However, with the right tools and techniques, cast iron can still be machined effectively. In conclusion, choosing between cast iron and steel depends on the specific requirements of your application. Steel offers superior strength, durability, and machinability, making it suitable for a wide range of applications. Cast iron, on the other hand, excels in areas such as compressive strength, heat retention, and wear resistance. By understanding the unique properties of both materials, businesses can make informed decisions and select the most appropriate material for their needs.

Steel’s machinability makes it a popular choice in industries such as automotive, aerospace, and manufacturing, where precise machining is required. Cast iron, on the other hand, can be more challenging to machine due to its brittle nature. It is prone to producing vibrations during cutting operations, which can lead to tool wear and reduced surface finish. However, with the right tools and techniques, cast iron can still be machined effectively. In conclusion, choosing between cast iron and steel depends on the specific requirements of your application. Steel offers superior strength, durability, and machinability, making it suitable for a wide range of applications. Cast iron, on the other hand, excels in areas such as compressive strength, heat retention, and wear resistance. By understanding the unique properties of both materials, businesses can make informed decisions and select the most appropriate material for their needs.

Your comment submitted.