We shall discuss the modern steel manufacturing process with a furnace route step by step and there are six steps.

Steelmaking is the process of producing steel from iron ore and/or steel waste.

In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur, and excess carbon (the most important impurities) are removed from source iron, and alloy elements such as manganese, nickel, and chromium, to create various grades, vanadium and carbon are added. Steel. Steel.

Limiting dissolved gases (such as nitrogen and oxygen) and steel impurities (called “inclusions”) in the steel is also important to ensure the quality of molten steel castings. Although steelmaking has been practiced for thousands of years, it wasn’t heavily marketed until the middle of the 19th century.

The crucible method is a traditional steelmaking technique. The Bessemer process and the Siemens-Martin process turned steelmaking into a major industry in the 1850s and 1860s. Principal oxygen steelmaking, which uses pig iron and blast furnace scrap as its primary feedstock, and electric arc furnace steelmaking, which uses scrap or direct use, are the two main commercial techniques for making steel today.

The primary raw ingredient is reduced iron (DRI). Oxygen steelmaking is primarily provided by the exothermic nature of the reactions in the vessel; In contrast, in electric arc furnace steelmaking, electrical energy is used to melt solid waste and/or DRI materials.

In recent years, EAF steelmaking technology has moved closer to oxygen steelmaking as more chemical energy is introduced into the process.

Steelmaking is one of the highest carbon industries in the world. As of 2020, steelmaking accounts for 7-9% of all direct fossil fuel emissions. To reduce global warming, the industry needs to reduce greenhouse gas emissions.

[4] In 2020, McKinsey identified several decarbonization technologies, including the use of hydrogen, carbon capture, and reuse, and maximizing clean energy electric arc furnaces. The modern steelmaking process, which began in the late 17th century, has come a long way, from the early open furnace process to the advanced electric furnace.

The industry is constantly conducting research and development to improve the quality and application of alloys and reduce defects. Global developments increase the demand for steel production. Here are 6 key steps modern steelmakers use to produce quality products:

Iron making Iron is the main raw material for steelmaking. Its raw form is iron ore, which is smelted in a blast furnace with lime and coke to obtain a more refined material. The result of this melting is molten iron, which is very brittle in metallic form due to carbon impurities.

Primary steelmaking: Once the molten iron is ready, the primary steel process can begin. There are two common modern stages in primary steel production; Basic Oxygen Furnace (BOS) and Electric Arc Furnace (EAF) using different steelmaking systems.

As implied by its name, BOS requires oxygen throughout its operation. Scrap (recycled steel) is added to the molten iron in the converter and oxygen is passed through this liquid solution at a high temperature to reduce the carbon impurities.

For the EAF method, scrap or sponge iron and molten iron are mixed in an electric furnace at a temperature of 1650°C to form high-quality molten steel.

Secondary steelmaking: The next step in steelmaking is processing the molten steel produced in primary steelmaking to achieve the desired alloy composition. Controlling the temperature of the molten steel or removing/adding certain elements. Stirring, ladle injection, degassing, argon bubble, etc. are processes that can be used to achieve the desired quality and type of steel.

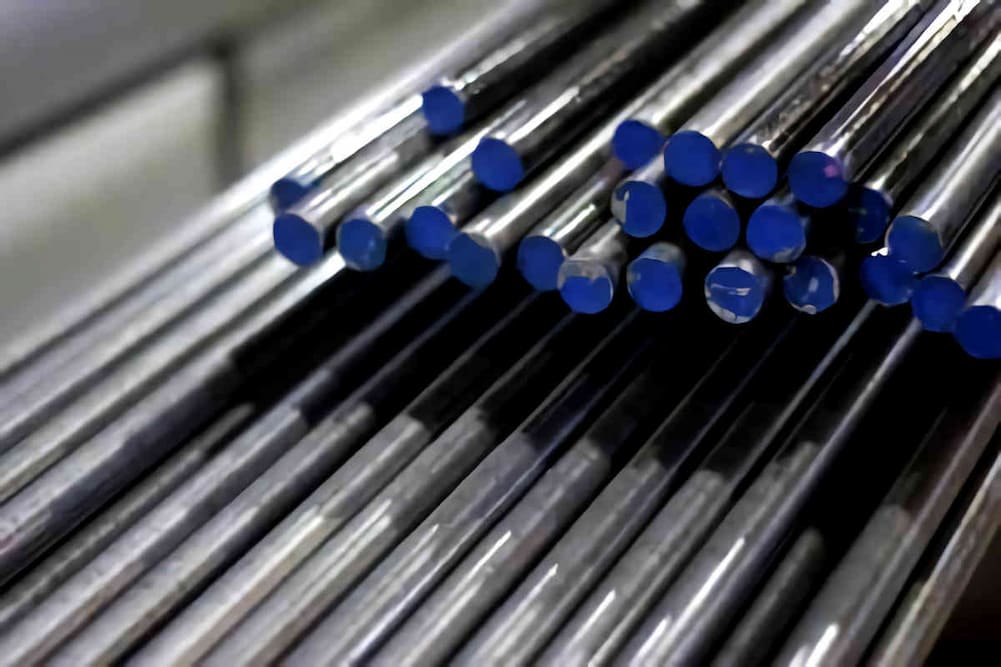

Continuous Casting: This step is very important for the production process. Molten steel is solidified in various casting molds to form semi-finished products, billets, blooms, or slabs, which can be further refined in a rolling mill. These semi-finished products have different applications, blank sheets are used for long products such as rods and wires; Flowers are mostly used to make sections and beams; Slabs are used to make flat products such as sheets and strips.

Primary molding: Semi-finished blooms, slabs, and billets are usually further processed without adding or removing any material from the product.

When hot rolled, these semi-finished products reach the desired shape and eliminate any casting defects without loss of quality. After hot rolling, these formed products are divided into long tubes, flat tubes, seamless tubes, and special products.

Secondary molding: It is the final stage in steel making and includes various fabrication, finishing, and fabrication processes. This stage develops the steel through various methods of forming, galvanizing, welding, tempering, and drilling to give it its final shape and properties.

Since the beginning of the Industrial Revolution process in the mid-19th century, the methods of steel production have changed dramatically. However, modern methods are still based on the Bessemer process, which was carried out over 150 years ago.

It is a method of introducing oxygen into molten iron to reduce the amount of carbon in it. At Agni Steels, we are driven by quality and process management, we ensure that necessary steps are incorporated in our modern and state-of-the-art steel manufacturing department to deliver quality products consistently.

We have a customized process validated by industry standards to provide consistent, high-quality products and services.

Conclusion

All information mentioned above providing to the buyers who want to know and buy metal steel products with professional and innovative thoughts, and passionate and enthusiastic attitudes. Our vision is to be a standard for customized products and quality services so that we can build a good brand image for our company in the national and international markets with competitive prices and cheap shipping services.

We are eager to do what we do and strive to further the needs of our customers by providing quality products and services. And do not hesitate to any questions our support teams are available. For more information kindly visit our site.

Your comment submitted.