Understanding the Difference In the world of metal manufacturing, iron and pig iron are two terms that often get thrown around. While they may sound similar, they have distinct differences that are important to understand for any business operating in the industry. Iron, also known as pure iron or wrought iron, is a chemical element with the symbol Fe (from the Latin word ferrum). It is a lustrous, silver-gray metal known for its high tensile strength and malleability. Iron has been used for centuries in various applications, including construction, transportation, and manufacturing. Pig iron, on the other hand, is a specific type of iron obtained from the smelting of iron ore. It is the intermediate product between iron ore and steel.

.

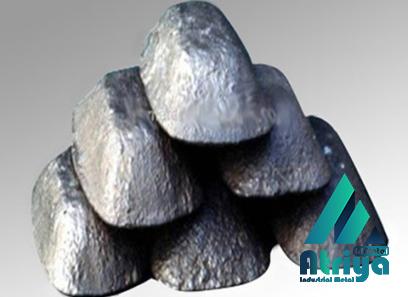

Pig iron gets its name from the method in which it is produced. The molten iron obtained from the blast furnace is poured into molds or pig molds, which resembles the shape of a piglet, hence the name pig iron. The key difference between iron and pig iron lies in their carbon content. Iron is almost entirely pure iron, with a carbon content of less than 0.03%. Pig iron, however, contains a higher carbon content, typically between 2% and 4%, along with other impurities such as sulfur, silicon, manganese, and phosphorus. The presence of these impurities gives pig iron its distinctive brittle nature, making it unsuitable for most applications.

Pig iron gets its name from the method in which it is produced. The molten iron obtained from the blast furnace is poured into molds or pig molds, which resembles the shape of a piglet, hence the name pig iron. The key difference between iron and pig iron lies in their carbon content. Iron is almost entirely pure iron, with a carbon content of less than 0.03%. Pig iron, however, contains a higher carbon content, typically between 2% and 4%, along with other impurities such as sulfur, silicon, manganese, and phosphorus. The presence of these impurities gives pig iron its distinctive brittle nature, making it unsuitable for most applications.

..

While iron is known for its malleability and relatively low carbon content, pig iron’s high carbon content and impurities make it an undesirable material for direct use. However, pig iron serves as a crucial raw material in the production of steel. It undergoes further refining through a process called steelmaking, where the carbon content is reduced, impurities are removed, and other alloys are added. The transformation of pig iron into steel involves two primary methods: the basic oxygen process (BOS) and the electric arc furnace (EAF) process. Both methods involve melting the pig iron and incorporating various alloys to achieve the desired steel properties. Iron and pig iron play different roles in the metal manufacturing industry.

While iron is known for its malleability and relatively low carbon content, pig iron’s high carbon content and impurities make it an undesirable material for direct use. However, pig iron serves as a crucial raw material in the production of steel. It undergoes further refining through a process called steelmaking, where the carbon content is reduced, impurities are removed, and other alloys are added. The transformation of pig iron into steel involves two primary methods: the basic oxygen process (BOS) and the electric arc furnace (EAF) process. Both methods involve melting the pig iron and incorporating various alloys to achieve the desired steel properties. Iron and pig iron play different roles in the metal manufacturing industry.

…

Iron is utilized in applications where its malleability and low carbon content are essential, such as in wrought iron products or as a component in alloy production. Pig iron, on the other hand, serves as a vital raw material for steel production, which is widely used in construction, machinery, automobiles, and countless other industries. In conclusion, understanding the difference between iron and pig iron is crucial for businesses operating in the metal industry. While iron offers malleability and low carbon content, pig iron serves as a crucial intermediate material in the production of steel. By comprehending their unique properties and applications, businesses can make informed decisions about the most suitable material for their specific needs.

Iron is utilized in applications where its malleability and low carbon content are essential, such as in wrought iron products or as a component in alloy production. Pig iron, on the other hand, serves as a vital raw material for steel production, which is widely used in construction, machinery, automobiles, and countless other industries. In conclusion, understanding the difference between iron and pig iron is crucial for businesses operating in the metal industry. While iron offers malleability and low carbon content, pig iron serves as a crucial intermediate material in the production of steel. By comprehending their unique properties and applications, businesses can make informed decisions about the most suitable material for their specific needs.

Your comment submitted.