Galvanized sheets are usually steel or iron sheets that are coated with a layer of zinc by one of the two galvanizing methods, which are also used in roofing due to their properties, and are traded per ton in different countries. Galvanized sheet is used in areas that are mostly humid or in direct contact with air, as these types of sheets are more resistant to corrosion and rust than base metals.

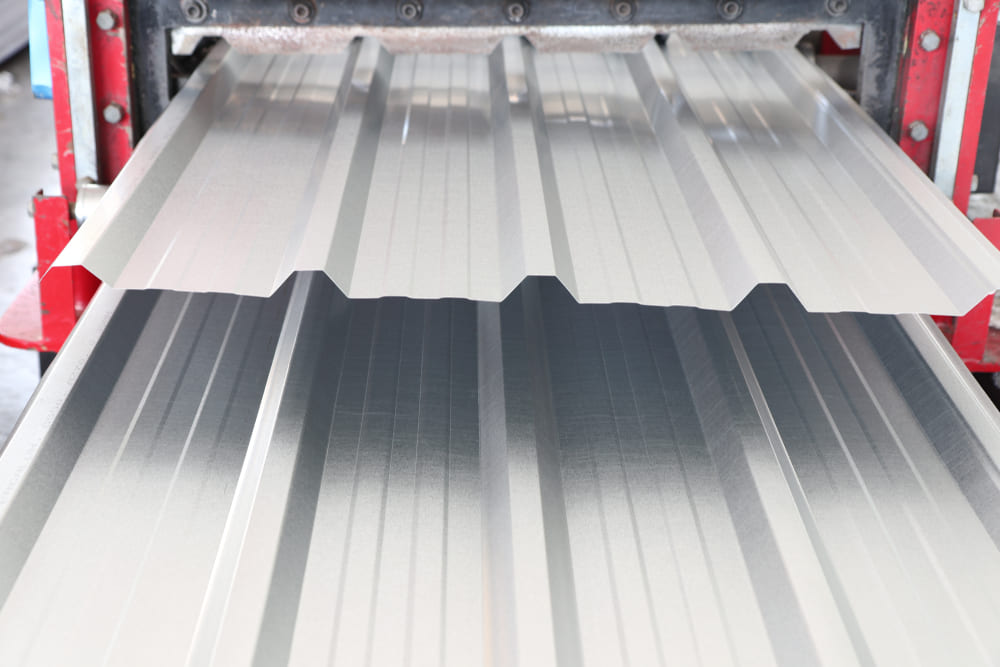

These sheets are used to cover the pitched roofs of sheds, livestock farms, factories or gables, and villas and are available in plain or colored galvanized form.

Iron rusts or oxidizes when iron or iron alloys come into contact with air or oxygen and moisture for long periods of time.

This connection is slow, so when steel is in prolonged contact with oxygen or moisture, chemical bonding occurs between the iron and oxygen atoms, creating a new compound called iron oxide that weakens the iron bond. Moisture or water increases the rate of this reaction and forms a compound called iron and hydrogen hydroxide.

After the iron has reacted to form an oxidized surface, the anode surface is formed, and elsewhere where there is water and oxygen, the cathode is formed. This causes a small voltaic process to occur on the surface of the iron and corrosion occurs as the anode moves towards the cathode.

Color galvanized

Galvanizing is a process of applying a zinc coating to the base metal, which makes the base iron resistant to erosion, corrosion and discoloration.

Galvanizing comes in two ways, hot and cold. In hot-dip galvanizing, the base metal is placed in a bath of molten zinc, so that a layer of zinc is formed on the base metal and the layer under the iron is mixed with the zinc. In cold galvanizing, zinc salts are sprinkled with water or acid on the base metal to form a thin layer of zinc metal to prevent rust and corrosion of the base metal.

In the hot galvanizing method, our galvanized surface is thick and matte, while in the cold galvanizing method, our surface becomes thin and glossy. This metal can be painted in various ways and can be used for fences, pitched roofs, ranch and villa roofs, etc.

How to paint galvanized sheet

Cold galvanized plate is used for painted galvanized plate. For this reason, the smooth surface of our galvanized sheet is difficult to paint, and in the next step, drying the paint requires special skills and tools.

There are two ways to paint the galvanized sheet. The first is that the galvanized plate is done by itself in the factory, and the oven painting method is used to spray the color on the plate as a single layer completely automatically. the colored paper will be uniform and have a sheen. In the second case, the paper is drawn by hand.

Before proceeding to implement a galvanized sheet roof, it is good to know more about the types of materials used for pitched roofs. The materials used for the roof are divided into different categories according to their gender, such as wooden shingles, andorin, OSB, acrowa, andovera and concrete shingles.

Each of these materials differs not only in appearance, but also in physical and chemical properties, resulting in differences in their implementation, quality and final price. Among the types of materials that can be used to implement the roof, galvanized sheet is very popular. If you want to learn more about the material and how to make galvanized sheet, don’t miss reading what is galvanized sheet.

Metal roofing sheets are one of the most durable products for all types of roofs. Sheet metal may cost more than other materials such as PVC, but it is more economical due to its longer lifespan. The implementation of the roof is usually made of colored galvanized sheet, which is more beautiful and durable.

In addition, the galvanized sheet has very good formability. For this reason, these slabs are shaped into different clay or slate shapes and used in different projects with widely different looks. Trapeze, shadow line, sine, Palermo clay, crochet clay and genial are the most popular designs of galvanized sheets.

How to achieve a gable roof with galvanized sheet

After you have chosen the design of the galvanized sheet to cover the roof, it is time to implement the roof. The implementation of a galvanized sheet roof has different steps.

The roof of the infrastructure can be made of metal, wood or profiles, which are connected to each other and to the metal frame of the building in the form of beams and rafters. They can also use layers of glass wool to insulate the roof.

With the right infrastructure and high-quality galvanized sheet, you can start working on your roof. The choice of sheet thickness and width depends on factors such as environmental conditions and roof location.

Steps for implementing a galvanized gable roof

To implement a gable roof, the galvanized sheet must first be cut. In general, the length of a sheet is considered to be 9.8 meters. You can cut the plate with a router, circular saw or scissors. In the next step, if the board does not already have holes, punch holes in it to insert connections on it. A drill can be used to drill holes in the plate. Remember that on the outer edge of the roof, the hole must be 15 to 20 cm from the edge of the board.

The panels are then laid horizontally on the roof and connected to each other and to the roof beams with polycarbonate screws and washers. The point of this step is that each sheet should be at least 5 cm higher than the previous sheet. If the roof slope is two-sided, perform the same steps on the other side and use a cap on top of the roof where the two sides meet.

Here are some key points for the implementation of pitched roofs, compliance with these points will help improve the quality of implementation:

- The edges of the paper must be fully engaged with each other.

- Accessories must be inserted into the upper surface.

- The sheets overlap each other by at least 5 cm, so be aware that the useful width of the sheets is less than their actual width.

galvanized sheet metal roofing in different countries

Gable roofs are not the only type of roof that uses galvanized metal sheet roofing. The steel deck roof is also made using galvanized sheet steel in different countries.

Steel decks are one of the newest ways to implement a roof. One of the most effective factors in the cost of implementing a steel deck roof is the price of galvanized sheet. A trapezoidal galvanized sheet is used to make these roofs. Due to this bending, the sheet is not deformed when it goes and the resistance is greater.

To achieve a steel deck roof, steel plates are used at the deck location. First, the galvanized sheets are stacked on top of each other with their edges on top of each other.

The parts must be placed together in such a way that they do not add additional loads to the structure. Then they use nails to join them together. In the next step, they welded the studs to the plate. Studs connect the steel deck to the rest of the components and provide better shear force transfer between concrete and steel.

The precise implementation of the roof in the building is very important. The roof must not only support its own weight, but must also be able to withstand additional loads from various environmental factors such as rain, wind, hail and snow.

In addition, the fire and earthquake resistance of the roof is very important. For this reason, it is very important to choose a suitable and cost-effective product to implement the suspended ceiling. Galvanized roofing sheets have many advantages that make them a top priority for roof construction on many projects.

- Relatively low weight

- Earthquake and fire resistance

- Rust resistance

- Suitable for wet and rainy areas

- Different colors and shapes for aesthetic appeal

- Reasonable price, long life, and good quality

- Simple and quick installation

How to make galvanized sheet

The fabrication and production steps for galvanized sheets vary depending on the process chosen. The iron housekeeper will introduce you to the steps of dip galvanizing or hot-dip galvanizing:

The fabrication and production steps for galvanized sheets vary depending on the process chosen. The iron housekeeper will introduce you to the steps of dip galvanizing or hot-dip galvanizing:

1- Phase 1:

- A) Preparation: If the plate is in coil form, the plate can be galvanized continuously or prepared for cutting.

- b) Degreasing: Degrease the plate with soda water.

2- Second phase

- A) Wash: The remaining degreasing solution on the sheet is washed in this step.

- b) Rust removal: The rusted plate is soaked in the hydrochloric acid descaling solution.

3- The third phase

- A) General cleaning: General cleaning if rust is removed from the plate.

- b) Flux: In this step, the plate surface is prepared for operation by a flux which is a combination of zinc chloride and other elements. The process is to mix zinc metal and steel.

- c) Isothermal: To prevent the metal from splashing onto the melt when immersed in the molten pool, a preheating process is used for isothermal. Normally, the temperature will rise to 80 degrees Celsius.

4- Fourth stage

Galvanizing: Immersion in the molten zinc bath

5- Fifth stage

- a) cooling

- b) cleaning

- c) Final inspection

What is the galvanized sheet?

There are generally two methods of galvanizing, cold galvanizing and hot galvanizing. To perform electroplating, it is first cleaned by various methods, such as using degreasing solutions, emulsions, industrial solvent cleaning, and steam degreasing, which is the process of forming viscous products.

After this step, pickling begins, where the item is placed in a solution of water, hydrochloric acid, or sulfuric acid. The acid concentration of the solution should be between 10 and 15% and its temperature should be between 60 and 80 degrees. Finally, it is galvanized and galvanized.

Shape and forming of galvanized sheet:

The thickness of the galvanized sheet can be an effective factor in its formability. Low-thickness galvanized sheet is well-formed by various simple machines.

Higher thicknesses are mainly used for connections. All types of welded and non-welded joints can be used to manufacture galvanized sheet products.

As already mentioned, galvanized sheets can also be individually shaped and are available on the market with specific designs, the most important of which are steel decks and shutters (sinusoidal). It should be pointed out here that in many similar places steel floor slabs are classified in the category of non-ferrous steel slabs, which is a form of galvanized sheet.

Application of galvanized sheet

Galvanized sheet is widely used in industry. From household appliances and the electrical and electronic industry to the automotive industry and industrial construction and transport equipment. Some places in the above projects have been occupied by galvanized sheets for many years.

For example, in the manufacture of household appliances such as refrigerators, air conditioners and residential ventilation ducts, all of which have moist and corrosive environments.

In the electrical industry for wiring lines, in the electronics industry for preparing covers, in the automotive industry for partition doors, in industrial buildings for the construction of sandwich panels, in traffic equipment for the construction of guardrails If we are Preparing a summary list for the use of the galvanized sheet, we can refer to the following list:

- Manufacture of household appliances

- Electricity, electronics, and computers

- Construction of galvanized silos

- industrial building

- Production of galvanized rabbit

- put up

- The automotive industry

- road work

Regarding the third case, it can be said that silos or warehouses for the storage of human and animal feed are made of both concrete and metal types, the metal type is made of roll-shaped galvanized sheets. See Figure 6. The construction of metal silos has its own advantages.

These include low construction costs, long life, easy maintenance and replacement, the ability to create an era of temperature control and add ventilation and ventilation systems, easy cleaning, and the ability to separate the hives.

Your comment submitted.