The galvanized Roofing of large industrial and commercial buildings and various constructional buildings is one of the industries where colored sheets are widely used in different variety and size, and due to the price and advantages of colored panels on the roofs of houses and other buildings, it is a good choice for the job. It seems that as the anatomy of the human body has evolved, so has the want and need for colored sheets; this type of worksheet makes things easier and is of a higher quality than similar examples.

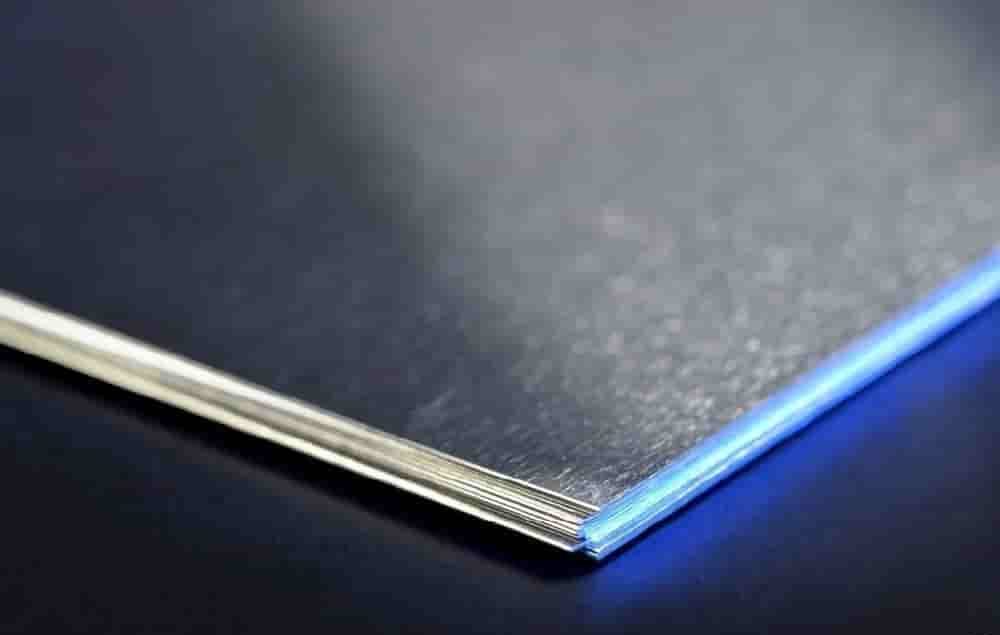

A color plate is also called a pre-color plate, which is actually a color galvanized plate. What distinguishes colored sheets from other sheets is the way these sheets are painted, which gives colored sheets on the roof of a house an advantage over other sheets.

Electrostatic methods are used to color these papers. This method not only gives the sheet a special aesthetic and effect but also increases its resistance and durability. In addition, colored metal sheets become more resistant to moisture and corrosion due to electrostatic painting. All these factors make these sheets widely available and at the same time unique.

Read more: Steel Rebar Wholesale

What are the electrostatic colors used in the coloring process for coloring pages?

As we have mentioned, electrostatic spray painting is an important factor affecting the performance and application of colored plates. In this method, the flakes are placed on the negatively charged ground. They then sprinkled a resin powder coating on the surface of the positively charged galvanized sheet. This opposite charge makes it easy for colored particles to stick to metal surfaces. Then put the plate in the oven until the color is baked through. The end result is a colored board that, in addition to being glossy and aesthetic, is resistant to many external harmful elements.

Features and benefits of using colored sheets on roofs

In the rest of this article, we will explain to you the unique features that create the benefits of colored sheets on the roof of your house:

- Color paper fireproof

In some cases, colored sheets are also made of aluminum, a material that is non-combustible and fire-retardant. Considering the low price of colored galvanized sheet, this sheet can be a good choice to protect the roof of factories, warehouses, houses, etc.

- Coloring pages are light in weight

The light weight of this sheet is another advantage of the house roof color sheet, as it is made of aluminum. In fact, the weight of the color sheet is much lower than the weight of the same product in the same category and the same volume. Also, the cost of the colored panels used to cover the roof is much lower than other panels used to cover the same roof. Also, colored boards are more durable than boards made of other materials.

Read more: Hot Rolled Steel Manufacturers

- Color plate anti-rust

As we said, one of the advantages of some colored panels on the roof of a house is that it is made of aluminum, and when this metal is exposed to the air, a thin layer of aluminum oxide forms on it, creating resistance. Good rust and corrosion protection. Therefore, the roof covered with colored aluminum sheets is not damaged by strong sunlight, wind, and rain.

Colored sheets are dyed with a complex chemical process that preserves their color for a long time against external damage.

- Confetti gives the ceiling a very beautiful effect

Hotels, restaurants, airports, office buildings, and other places that pursue architectural aesthetic value should use colored plates. In fact, one of the advantages of colored tiles on the roof of a house is that it doubles their beauty.

- Coloring pages are very durable

Colored aluminum sheets are very stable and durable. In fact, one of the advantages of the color board on a house roof is that it maintains its rigidity well under different weather conditions and can withstand heavy loads. Be sure to use this table if you want to save on roofing costs; coloring pages are more durable than other types of materials used for roofing.

What is colored paper for?

As we mentioned, the main advantage is the colorful tiles on the roof of the house. This type of sheet, also known as gable colored sheet, is widely used in various industries such as construction. Some other common uses of colored paper are as follows:

- Bodywork and roofs for workshops, warehouses, and sheds

- building exterior

- Decorative facades for houses, businesses, and…

- The main part of industrial machinery and steam boilers

- The body of various household appliances such as refrigerators, water heaters, washing machines, etc.

- computer case

- Carpentry and other metal industry

- cool storage

- False ceilings and…

The advantages of galvanized sheet

- There are many advantages to using galvanized sheet which are briefly described below:

- Low cost: Galvanizing requires less cost than other corrosion protection methods.

- Long life: These galvanized sheets have a life of approximately 20 to 30 years in a fully corroded and rusty environment.

- Durability: The galvanized coating will have good resistance to mechanical damage, wear and corrosion due to its special metal structure.

- EASY TO USE: If you need to use galvanized sheet, you do not need to spend time on surface treatment, painting, etc.

Application of galvanized sheet:

Application of galvanized sheet:

Types of galvanized sheet have different uses and are made of different materials. The application of galvanized sheet is very wide. Galvanized sheet is everywhere! The bodies of many cars and bicycles are made of galvanized sheet, some drinking water pipes are made of galvanized steel, cold-rolled sheets are also often galvanized, and various bolts, tools and wires are now galvanized, because it is a cheap process and it helps to extend lifetime of the metal. Galvanized steel is also particularly commonly used in modern “steel frame” construction. It is also used to create structures such as balconies, porches, stairs, passageways, etc. Galvanized metal is an ideal choice if your project will remain outdoors after completion. Fences, roofs and outdoor walkways are all good choices for galvanized metal.

Use of galvanized sheets in the construction industry: Whether residential or commercial, the durability of galvanized steel has made it popular in the construction industry for over a century. It was also chosen for construction because of its beauty. The sheen of galvanized sheets creates a modern look and is therefore common in modern architectural designs. In addition, the use of galvanized sheets in the construction industry is not limited to large structural parts, but also includes fences, gutters, pipes, columns, and other items. The use of galvanized roofing sheets is one of the most common uses of galvanized sheets today.

Read more: Steel Sheet Wholesalers

galvanized roofing sheet in constructional building

Galvanized roofing sheet is a sheet made of ferrous metal and coated with zinc. Various metal sheets are used in very large quantities in industry and are used in constructional building. There are different types of sheet metal, classified by the type of material used in them and how they are made.

Application of galvanized sheet in the wind and solar industry: After the solar project is installed, there must be a continuous workflow, any maintenance will cause service interruption. This means that galvanized steels are popular in solar projects because they prevent corrosion and rust.

They are also popular for being environmentally friendly as they do not produce pollutants and are guaranteed to be maintenance-free for decades. For example, it is often used in the agricultural industry, as these devices are susceptible to corrosion and decay, creating a need for more durable and flexible equipment. The corrosion protection these products provide typically lasts for decades, even when exposed to harsh agricultural environments.

Automotive: While galvanized sheet metal was not used in luxury cars until the 1980s, the use of galvanized bodywork in automobile manufacturing is now the norm. When assembling the car frame, which makes up around 80% of the body, galvanized steel is used for all parts.

In addition, the corrosion resistance of galvanized steel is an appropriate marketing tool for the automotive industry, as it can provide customers with the assurance that it will not rust.

The application of galvanized sheets in the communication industry: the maintenance of telephone lines is not an easy task, and the telephone lines are long and difficult to connect. Galvanized sheets can be used on telephone lines and equipment boxes, reducing the risk of damage and the need for maintenance.

Various metal sheets

There are different types of sheet metal, each serving a different purpose. Sheet metal is divided into seven categories according to raw materials and production methods, namely: galvanized sheet, oiled sheet, corrugated sheet, blackboard, color sheet, steel sheet, and pickling sheet. Below we will examine these types of worksheets.

Galvanized sheet metal

A sheet of metal coated with metal is called galvanized sheet. The coating formed on the plate prevents corrosion and turns the plate into a stainless steel plate.

black metal plate

Sheets produced by hot rolling are called boards. These types of sheets are available in various sizes in the market and have various applications in various industries such as automobile manufacturing, building construction, pipe manufacturing, etc.

colored sheet metal

Colored sheet metal is actually the same galvanized sheet with a certain color added to the surface in a furnace and used for different purposes.

Pickling of metal sheets

These types of sheets are black sheet that has been pickled to remove carbon and impurities from the surface.

oiled paper

Plates produced by cold rolling are called oil plates. These sheets are small in thickness and have a very good appearance quality.

Use of various metal sheets in the industry

Plates are used in a wide range of industries, from construction to the oil and gas industry, and are used all over the world. We discuss the use of different types of sheet metal in industry:

One of the possible uses for sheet metal in the industry is the automotive industry, where ferrous sheets are used. Steel plates are used in the shipbuilding industry, construction of external walls, etc. Galvanized sheet is used in wet areas and where the sheet is susceptible to corrosion. Another industrial use of sheet metal is in the home appliance manufacturing industry. They usually use colored plates on the main body of refrigerators, water heaters, washing machines, gas stoves, etc.

Shutters and their use in industry

If we convert galvanized sheets or colored sheet to shaped state, we will have a slatted panel. This sheet in a variety of colors and designs is widely used in today’s industry. Among the first designs of shutters, we can mention the sinusoidal shutters available in the market.

Corrugated shutters are used to cover the gable roof and various materials are used in their construction. After technological progress and popularization in Iran, galvanized corrugated sheet was first used in the houses of the upper-income class, but with the passage of time and the popularity of the use of bending machines and forming iron sheets into corrugated shapes, it became more and more. more Construction became popular.

The reason galvanized sheets are painted is for durability and efficiency, which also gives them a special aesthetic, so they are used on roofs to prevent rot and physical damage.

Aluminum zinc plate

The plate is made of aluminum-coated steel. This is an aluminum coating that protects the plate against rust and oxidation. Using this sheet increases the life of the sandwich panel. Among the advantages of Aluzinc sheets, it can be mentioned that these sheets are a more suitable alternative to aluminum and galvanized sheets for buildings erected in wet weather conditions. Aluzinc plates generally have a longer life and higher durability than galvanized plates.

Roof plate (sinusoidal) and manufacturing method

Gable panels are mainly used to cover the roofs of various buildings, workshops, sheds, greenhouses, false roofs, etc. 5 main steps to make these papers:

At the beginning, we choose the type of plate and material required, depending on where the structure is to be placed. 2- We choose the appearance of the desired structure. 3- According to the customer’s taste, we choose the desired color and design. 4- Calculate incidental costs and required time 5- Implementation phase

Whether these papers are colored or not depends on their application, of course sine gable board is more practical than other papers. The appropriate weight of the corrugated sine plate is determined by the customer’s taste or standard. The weight of the sinusoidal lamella mainly follows the weight of the galvanized plate.

Its length is also specified according to the buyer’s preference, but by default sheets of 2 to 6 meters in length are always ready to ship.

Your comment submitted.