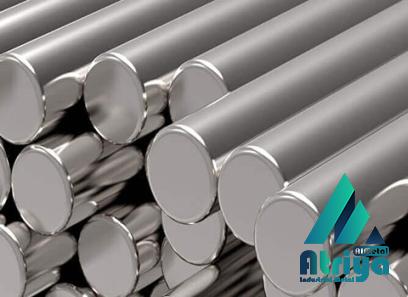

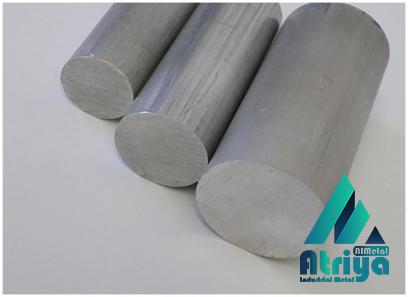

A Strong Solution for Precise Specifications In various industries and applications, the need for precision and strength is paramount. One such component that meets these requirements is the drilled aluminium bar. With its exceptional durability, versatility, and ease of machining, it has become a popular choice among manufacturers and engineers. Drilled aluminium bars offer numerous advantages, making them an ideal material for a wide range of applications. Their excellent weight-to-strength ratio makes them an attractive option in industries where lightweight yet sturdy components are required. Additionally, the corrosion resistance of aluminium ensures longevity even in harsh environmental conditions. One of the key benefits of drilled aluminium bars is their versatility. They can be tailored to specific specifications, allowing for precision drilling and machining.

.

This is particularly important in industries such as aerospace, automotive, and electronics, where intricate customization is needed. Drilled aluminium bars can be expertly tailored to meet specific requirements, including precise hole placement, diameter, and depth. These bars can be drilled in a variety of patterns, including linear, irregular, or customized designs to fulfill the unique needs of various projects. This flexibility allows manufacturers to achieve the desired functionality and aesthetic appeal. The drilling process itself is crucial in ensuring the quality and reliability of the drilled aluminium bars. By utilizing advanced drilling techniques, manufacturers can achieve high precision and accuracy, providing clients with products that meet the most demanding requirements. These techniques may involve computer-controlled drilling machines, laser-guided systems, or other cutting-edge technologies. Industries benefiting from drilled aluminium bars are vast and diverse.

This is particularly important in industries such as aerospace, automotive, and electronics, where intricate customization is needed. Drilled aluminium bars can be expertly tailored to meet specific requirements, including precise hole placement, diameter, and depth. These bars can be drilled in a variety of patterns, including linear, irregular, or customized designs to fulfill the unique needs of various projects. This flexibility allows manufacturers to achieve the desired functionality and aesthetic appeal. The drilling process itself is crucial in ensuring the quality and reliability of the drilled aluminium bars. By utilizing advanced drilling techniques, manufacturers can achieve high precision and accuracy, providing clients with products that meet the most demanding requirements. These techniques may involve computer-controlled drilling machines, laser-guided systems, or other cutting-edge technologies. Industries benefiting from drilled aluminium bars are vast and diverse.

..

In aerospace applications, they are used in the assembly of aircraft structures, providing strength without excessive weight. In the automotive sector, drilled aluminium bars find application in engine components, suspension systems, and structural elements, contributing to enhanced performance and fuel efficiency. Furthermore, electronic manufacturers use drilled aluminium bars to produce lightweight and durable enclosures for various devices. To ensure the highest quality, it is essential to source drilled aluminium bars from reputable suppliers. Manufacturers with a proven track record and expertise in aluminium processing can offer reliable and tailor-made solutions. Compliance with industry standards and the use of high-quality aluminium alloys are factors that should be taken into consideration when selecting a supplier.

In aerospace applications, they are used in the assembly of aircraft structures, providing strength without excessive weight. In the automotive sector, drilled aluminium bars find application in engine components, suspension systems, and structural elements, contributing to enhanced performance and fuel efficiency. Furthermore, electronic manufacturers use drilled aluminium bars to produce lightweight and durable enclosures for various devices. To ensure the highest quality, it is essential to source drilled aluminium bars from reputable suppliers. Manufacturers with a proven track record and expertise in aluminium processing can offer reliable and tailor-made solutions. Compliance with industry standards and the use of high-quality aluminium alloys are factors that should be taken into consideration when selecting a supplier.

…

As always, when working with any type of material, it is crucial to consider sustainability and environmental factors. Aluminium is known for its recyclability, making it an environmentally friendly choice. By utilizing drilled aluminium bars, manufacturers can contribute to a circular economy and embrace sustainable practices. In conclusion, drilled aluminium bars offer immense value and versatility in various industries. Their exceptional strength-to-weight ratio, corrosion resistance, and ability to meet precise specifications make them an optimal choice for demanding applications. By partnering with reputable suppliers and embracing sustainable practices, manufacturers can harness the advantages of drilled aluminium bars to create innovative and reliable products.

As always, when working with any type of material, it is crucial to consider sustainability and environmental factors. Aluminium is known for its recyclability, making it an environmentally friendly choice. By utilizing drilled aluminium bars, manufacturers can contribute to a circular economy and embrace sustainable practices. In conclusion, drilled aluminium bars offer immense value and versatility in various industries. Their exceptional strength-to-weight ratio, corrosion resistance, and ability to meet precise specifications make them an optimal choice for demanding applications. By partnering with reputable suppliers and embracing sustainable practices, manufacturers can harness the advantages of drilled aluminium bars to create innovative and reliable products.

Your comment submitted.