A Comprehensive Comparison In the world of manufacturing and construction, steel plays a pivotal role owing to its vast array of applications and benefits. However, within the realm of steel, there are different variations that serve distinct purposes. This article aims to provide a comprehensive comparison between two commonly used types: cold rolled steel and mild steel. 1. Manufacturing Process The primary differentiator between cold rolled steel and mild steel lies in their manufacturing processes. Cold rolled steel is produced from a hot-rolled coil, which undergoes additional processing to achieve its desired characteristics. This process involves rolling the steel at room temperature, resulting in a smoother, more refined finish. On the other hand, mild steel is manufactured using the hot rolling process, where the metal is heated beyond its recrystallization temperature and then rolled. 2. Strength and Durability Cold rolled steel possesses enhanced strength and durability compared to mild steel.

.

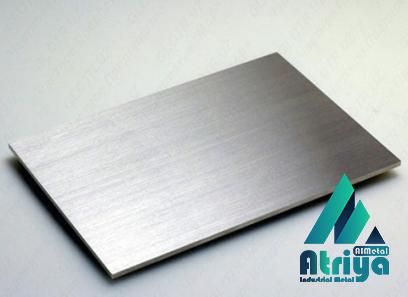

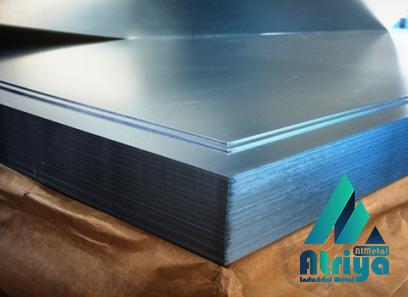

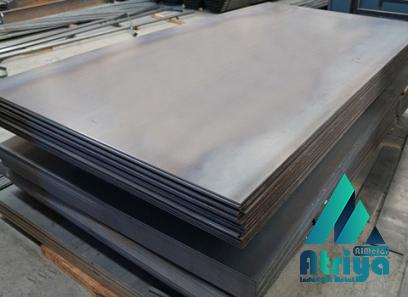

The cold rolling process improves the hardness and tensile strength of the steel, making it ideal for applications requiring high strength, such as automotive components, machinery parts, and construction materials. Mild steel, although not as strong as cold rolled steel, still offers sufficient strength for various applications, including structural frames and general fabrication. 3. Surface Finish One of the most noticeable differences between cold rolled steel and mild steel lies in their surface finish. Cold rolled steel exhibits a smooth, polished appearance, free from imperfections and scale. This pristine finish makes it suitable for applications where aesthetics are crucial, such as architectural elements, appliances, and decorative finishes. In contrast, mild steel often retains a rougher surface finish due to the hot rolling process, making it more suitable for applications where appearance is less critical, such as structural components.

The cold rolling process improves the hardness and tensile strength of the steel, making it ideal for applications requiring high strength, such as automotive components, machinery parts, and construction materials. Mild steel, although not as strong as cold rolled steel, still offers sufficient strength for various applications, including structural frames and general fabrication. 3. Surface Finish One of the most noticeable differences between cold rolled steel and mild steel lies in their surface finish. Cold rolled steel exhibits a smooth, polished appearance, free from imperfections and scale. This pristine finish makes it suitable for applications where aesthetics are crucial, such as architectural elements, appliances, and decorative finishes. In contrast, mild steel often retains a rougher surface finish due to the hot rolling process, making it more suitable for applications where appearance is less critical, such as structural components.

..

4. Formability and Workability Both cold rolled steel and mild steel possess excellent formability and workability, but they differ in their limits and ease of manipulation. Cold rolled steel retains its shape and dimensional accuracy even when subjected to bending or shaping processes. Its superior formability makes it ideal for intricate designs and precision-engineered components. Mild steel, although less malleable than cold rolled steel, is still highly workable and suitable for a wide range of fabrication processes, including welding, cutting, and shaping. 5. Cost Considerations Cost is a significant factor to consider in any industry, and the price difference between cold rolled steel and mild steel can be substantial.

4. Formability and Workability Both cold rolled steel and mild steel possess excellent formability and workability, but they differ in their limits and ease of manipulation. Cold rolled steel retains its shape and dimensional accuracy even when subjected to bending or shaping processes. Its superior formability makes it ideal for intricate designs and precision-engineered components. Mild steel, although less malleable than cold rolled steel, is still highly workable and suitable for a wide range of fabrication processes, including welding, cutting, and shaping. 5. Cost Considerations Cost is a significant factor to consider in any industry, and the price difference between cold rolled steel and mild steel can be substantial.

…

Cold rolled steel is generally more expensive due to its refined manufacturing process and superior properties. Its enhanced strength, durability, and surface finish make it a preferred choice for applications that demand premium quality steel. Conversely, mild steel is more cost-effective, making it suitable for applications where strength and surface finish are not critical factors. In conclusion, both cold rolled steel and mild steel offer unique advantages and are selected based on specific requirements. Cold rolled steel provides enhanced strength, durability, and a polished finish, making it suitable for a range of applications. On the other hand, mild steel offers good strength and workability, at a more affordable price point. Understanding the differences between these two types of steel allows businesses to make informed decisions based on their specific needs, ensuring optimal performance and cost-effectiveness in their projects.

Cold rolled steel is generally more expensive due to its refined manufacturing process and superior properties. Its enhanced strength, durability, and surface finish make it a preferred choice for applications that demand premium quality steel. Conversely, mild steel is more cost-effective, making it suitable for applications where strength and surface finish are not critical factors. In conclusion, both cold rolled steel and mild steel offer unique advantages and are selected based on specific requirements. Cold rolled steel provides enhanced strength, durability, and a polished finish, making it suitable for a range of applications. On the other hand, mild steel offers good strength and workability, at a more affordable price point. Understanding the differences between these two types of steel allows businesses to make informed decisions based on their specific needs, ensuring optimal performance and cost-effectiveness in their projects.

Your comment submitted.