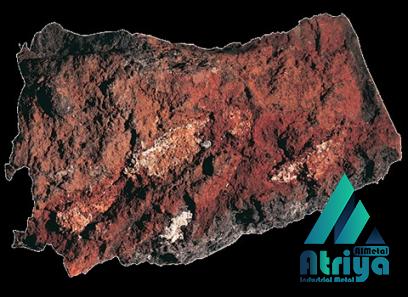

A Comprehensive Guide to a Vital Steelmaking Ingredient In the world of steel production, iron ore pellets play a crucial role. These small, spherical balls of concentrated iron ore are a key ingredient in the production of steel. They serve as a highly efficient and reliable feedstock for blast furnaces, providing a consistent source of high-grade iron ore that is essential for manufacturing high-quality steel products. Iron ore pellets are made by agglomerating fine iron ore particles into small, uniform spheres. This process involves mixing and compressing the iron ore fines with a binder, usually bentonite clay, and then indurating or heating them to a high temperature. The result is a strong and durable pellet that can withstand the rigors of transportation and handling. The advantages of using iron ore pellets in steel production are numerous. First and foremost, pellets offer a higher iron content compared to other forms of iron ore, such as fines or lumps.

.

This high iron content is crucial for producing good quality steel with desirable properties, such as strength, durability, and resistance to corrosion. Furthermore, the uniform size and shape of pellets ensure consistent and efficient performance in blast furnaces. The pellets’ small size allows for better mixing and distribution within the furnace, enabling more efficient combustion of the iron ore and reducing energy consumption. This translates into higher furnace productivity and lower production costs. Iron ore pellets are also less prone to sudden temperature fluctuations during the smelting process, minimizing the risk of furnace damage and improving overall operational stability. Their durability and resistance to degradation enable easy manipulation and handling, reducing the loss of iron ore fines and preventing environmental pollution.

This high iron content is crucial for producing good quality steel with desirable properties, such as strength, durability, and resistance to corrosion. Furthermore, the uniform size and shape of pellets ensure consistent and efficient performance in blast furnaces. The pellets’ small size allows for better mixing and distribution within the furnace, enabling more efficient combustion of the iron ore and reducing energy consumption. This translates into higher furnace productivity and lower production costs. Iron ore pellets are also less prone to sudden temperature fluctuations during the smelting process, minimizing the risk of furnace damage and improving overall operational stability. Their durability and resistance to degradation enable easy manipulation and handling, reducing the loss of iron ore fines and preventing environmental pollution.

..

The use of iron ore pellets as a feedstock for steel production offers environmental benefits as well. Compared to sinter or lump ore, the production of pellets emits fewer greenhouse gases and particulate matter, resulting in a lower carbon footprint. Additionally, the utilization of pellets helps reduce the consumption of natural resources, as their uniformity and superior quality ensure optimal utilization of iron ore reserves. The global demand for iron ore pellets is significant and continues to grow. Steel manufacturers across the world rely heavily on pellets to maintain the required iron input for their operations. Major steel-producing countries, such as China, India, and the United States, are key consumers of iron ore pellets, with emerging economies also showing increasing demand as they ramp up their steel production capacities.

The use of iron ore pellets as a feedstock for steel production offers environmental benefits as well. Compared to sinter or lump ore, the production of pellets emits fewer greenhouse gases and particulate matter, resulting in a lower carbon footprint. Additionally, the utilization of pellets helps reduce the consumption of natural resources, as their uniformity and superior quality ensure optimal utilization of iron ore reserves. The global demand for iron ore pellets is significant and continues to grow. Steel manufacturers across the world rely heavily on pellets to maintain the required iron input for their operations. Major steel-producing countries, such as China, India, and the United States, are key consumers of iron ore pellets, with emerging economies also showing increasing demand as they ramp up their steel production capacities.

…

To meet this growing demand, iron ore pellet producers continually strive to improve their operations and enhance the quality of their products. They invest in research and development to optimize the pelletizing process, explore alternative binders to reduce costs, and develop innovative technologies for pelletizing lower-grade iron ores. In conclusion, iron ore pellets are a crucial ingredient in steelmaking. Their high iron content, uniform size, and shape make them an ideal feedstock for blast furnaces, ensuring efficient and cost-effective steel production. Moreover, their environmental benefits make them a preferred choice for steel manufacturers worldwide. As the demand for steel continues to rise, the importance of iron ore pellets in the global steel industry is set to grow, making them an essential part of the steelmaking supply chain.

To meet this growing demand, iron ore pellet producers continually strive to improve their operations and enhance the quality of their products. They invest in research and development to optimize the pelletizing process, explore alternative binders to reduce costs, and develop innovative technologies for pelletizing lower-grade iron ores. In conclusion, iron ore pellets are a crucial ingredient in steelmaking. Their high iron content, uniform size, and shape make them an ideal feedstock for blast furnaces, ensuring efficient and cost-effective steel production. Moreover, their environmental benefits make them a preferred choice for steel manufacturers worldwide. As the demand for steel continues to rise, the importance of iron ore pellets in the global steel industry is set to grow, making them an essential part of the steelmaking supply chain.

Your comment submitted.