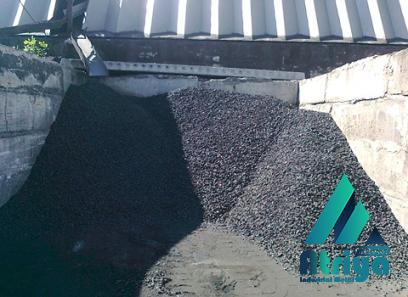

A Revolutionary Solution for Industrial Applications In recent times, the industrial sector has witnessed a significant surge in demand for innovative materials that can meet the challenges of modern manufacturing processes. One such material that has garnered attention is powdered iron 5e. This revolutionary form of iron has the potential to revolutionize the way industries operate, offering numerous advantages over conventional iron products. In this article, we will delve into the world of powdered iron 5e and explore its applications, benefits, and implications for the industrial sector. Powdered iron 5e, also known as atomized iron powder, is produced by a unique process called atomization. During this process, molten iron is subjected to high-pressure jets of gas or liquid, which break it into tiny droplets. These droplets then solidify into fine particles ranging from micrometers to millimeters in size.

.

The resulting powder possesses several distinctive characteristics that make it highly desirable for various industrial applications. One of the key benefits of powdered iron 5e lies in its superior flowability. The fine particles exhibit excellent fluidity, allowing for uniform distribution and easy mixing with other materials. This property is especially advantageous in applications such as metal injection molding, where the powder needs to flow through complex mold cavities and fill intricate shapes with high precision. Moreover, powdered iron 5e exhibits enhanced compaction properties, making it an ideal material for powder metallurgy. The small particle size and spherical shape of the powder allow for efficient packing and increased density during the compaction process. This leads to the production of dense and high-strength components, suitable for a wide range of industrial parts, such as automotive components, electrical contacts, and even magnetic cores for transformers. Another notable advantage of powdered iron 5e is its enhanced surface area.

The resulting powder possesses several distinctive characteristics that make it highly desirable for various industrial applications. One of the key benefits of powdered iron 5e lies in its superior flowability. The fine particles exhibit excellent fluidity, allowing for uniform distribution and easy mixing with other materials. This property is especially advantageous in applications such as metal injection molding, where the powder needs to flow through complex mold cavities and fill intricate shapes with high precision. Moreover, powdered iron 5e exhibits enhanced compaction properties, making it an ideal material for powder metallurgy. The small particle size and spherical shape of the powder allow for efficient packing and increased density during the compaction process. This leads to the production of dense and high-strength components, suitable for a wide range of industrial parts, such as automotive components, electrical contacts, and even magnetic cores for transformers. Another notable advantage of powdered iron 5e is its enhanced surface area.

..

The fine particles provide a large reactive surface area, making it highly reactive with other substances. This attribute lends itself well to applications such as catalysts for chemical reactions, where the increased surface area enhances the catalytic activity, resulting in improved reaction rates and efficiency. Additionally, powdered iron 5e offers significant energy savings in manufacturing processes. Due to its superior flowability, it requires less energy during transportation, handling, and mixing compared to traditional iron materials. Its excellent compaction properties also allow for reduced material wastage, resulting in cost savings and environmental benefits. The potential applications of powdered iron 5e are vast and diverse.

The fine particles provide a large reactive surface area, making it highly reactive with other substances. This attribute lends itself well to applications such as catalysts for chemical reactions, where the increased surface area enhances the catalytic activity, resulting in improved reaction rates and efficiency. Additionally, powdered iron 5e offers significant energy savings in manufacturing processes. Due to its superior flowability, it requires less energy during transportation, handling, and mixing compared to traditional iron materials. Its excellent compaction properties also allow for reduced material wastage, resulting in cost savings and environmental benefits. The potential applications of powdered iron 5e are vast and diverse.

…

Apart from its prominence in powder metallurgy and metal injection molding, it finds use in magnetic materials, sintered bearings, friction materials, and even as a raw material for the production of iron-based alloys. As industries continue to explore new possibilities, powdered iron 5e is expected to find even more innovative applications in the coming years. In conclusion, powdered iron 5e is a remarkable material that holds great promise for the industrial sector. Its outstanding flowability, compaction properties, reactive surface area, and energy-saving benefits make it an attractive option for various applications. As industries continue to seek efficient and cost-effective solutions, powdered iron 5e is likely to play a crucial role in shaping the future of manufacturing processes.

Apart from its prominence in powder metallurgy and metal injection molding, it finds use in magnetic materials, sintered bearings, friction materials, and even as a raw material for the production of iron-based alloys. As industries continue to explore new possibilities, powdered iron 5e is expected to find even more innovative applications in the coming years. In conclusion, powdered iron 5e is a remarkable material that holds great promise for the industrial sector. Its outstanding flowability, compaction properties, reactive surface area, and energy-saving benefits make it an attractive option for various applications. As industries continue to seek efficient and cost-effective solutions, powdered iron 5e is likely to play a crucial role in shaping the future of manufacturing processes.

Your comment submitted.