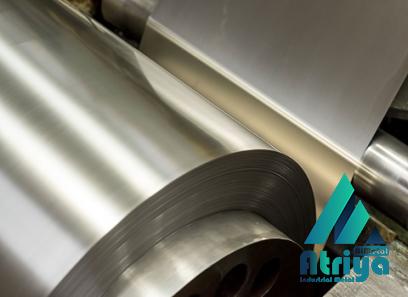

A Comprehensive Guide for Businesses When it comes to shaping and forming metals, one process that stands out is steel sheet bending. This versatile technique is employed across various industries and plays a crucial role in creating a wide range of products. In this article, we will delve into the world of steel sheet bending, exploring its applications, benefits, and key considerations for businesses. Steel sheet bending involves the process of deforming a flat sheet of steel into a desired shape. This can be achieved through the application of force, typically by using specialized machinery such as press brakes or rolling machines. The process can be carried out on different types of steel, including carbon steel, stainless steel, and aluminum, depending on the specific requirements of the project. One of the primary applications of steel sheet bending is in the manufacturing of metal enclosures and cabinets. These components are widely used in industries such as electronics, telecommunications, and automotive.

.

By bending steel sheets, manufacturers can create structurally sound enclosures that are both protective and aesthetically pleasing. Another significant application of steel sheet bending is in the construction sector. Steel is a preferred material for building frameworks, beams, and columns due to its strength and durability. By bending steel sheets to specific angles and shapes, builders can achieve the desired structural integrity, ensuring the safety and longevity of the constructed buildings. The benefits of steel sheet bending extend beyond its applications. One of the main advantages is its cost-effectiveness. Steel is a relatively inexpensive material, making it an attractive option for businesses looking to keep their production costs low. Additionally, steel’s intrinsic strength and ability to withstand harsh environmental conditions make it a reliable choice, reducing the need for frequent repairs or replacements.

By bending steel sheets, manufacturers can create structurally sound enclosures that are both protective and aesthetically pleasing. Another significant application of steel sheet bending is in the construction sector. Steel is a preferred material for building frameworks, beams, and columns due to its strength and durability. By bending steel sheets to specific angles and shapes, builders can achieve the desired structural integrity, ensuring the safety and longevity of the constructed buildings. The benefits of steel sheet bending extend beyond its applications. One of the main advantages is its cost-effectiveness. Steel is a relatively inexpensive material, making it an attractive option for businesses looking to keep their production costs low. Additionally, steel’s intrinsic strength and ability to withstand harsh environmental conditions make it a reliable choice, reducing the need for frequent repairs or replacements.

..

When considering steel sheet bending for business purposes, several key factors must be taken into account. Firstly, the choice of steel material will influence the success of the bending process. Different types of steel have varying levels of ductility, i.e., their ability to be bent without cracking or breaking. Selecting the appropriate grade of steel is crucial to ensure the desired shape is achieved while maintaining structural integrity. Another consideration is the equipment and machinery used for steel sheet bending. Investing in high-quality press brakes or rolling machines will result in precise and consistent bends, reducing the chances of inaccuracies or defects in the final product. Additionally, businesses should prioritize partnering with experienced and skilled metal fabricators who possess the necessary expertise to carry out complex bending projects.

When considering steel sheet bending for business purposes, several key factors must be taken into account. Firstly, the choice of steel material will influence the success of the bending process. Different types of steel have varying levels of ductility, i.e., their ability to be bent without cracking or breaking. Selecting the appropriate grade of steel is crucial to ensure the desired shape is achieved while maintaining structural integrity. Another consideration is the equipment and machinery used for steel sheet bending. Investing in high-quality press brakes or rolling machines will result in precise and consistent bends, reducing the chances of inaccuracies or defects in the final product. Additionally, businesses should prioritize partnering with experienced and skilled metal fabricators who possess the necessary expertise to carry out complex bending projects.

…

Furthermore, businesses should also be aware of the design limitations associated with steel sheet bending. Sharp bends, for instance, may lead to stress concentration and ultimately compromise the strength of the material. Careful consideration of design parameters and consulting with professionals can help businesses overcome such challenges and achieve the desired results. In conclusion, steel sheet bending is a widely used process in various industries, and its applications are vast and diverse. From manufacturing enclosures to constructing buildings, the versatility and cost-effectiveness of steel sheet bending make it an attractive choice for businesses. By considering factors such as steel material selection, equipment quality, and design limitations, businesses can ensure the successful implementation of steel sheet bending in their operations, leading to high-quality products and satisfied clients.

Furthermore, businesses should also be aware of the design limitations associated with steel sheet bending. Sharp bends, for instance, may lead to stress concentration and ultimately compromise the strength of the material. Careful consideration of design parameters and consulting with professionals can help businesses overcome such challenges and achieve the desired results. In conclusion, steel sheet bending is a widely used process in various industries, and its applications are vast and diverse. From manufacturing enclosures to constructing buildings, the versatility and cost-effectiveness of steel sheet bending make it an attractive choice for businesses. By considering factors such as steel material selection, equipment quality, and design limitations, businesses can ensure the successful implementation of steel sheet bending in their operations, leading to high-quality products and satisfied clients.

Your comment submitted.