With so many gadgets around, the steels you use every day are made from all of these many derivatives of steel. Cast iron steels, mild steels, and stainless steels, a type of alloyed steel, are all utilized in products. Our typical steel items can satisfy your needs for unique designs and uses.Iron Slabs are a type of raw material used in crafting that are produced in a Processor.

As is the case with everything else that may be manufactured in the Processor, there is no requirement to unlock any recipes in order to do so.It is possible to produce 2 Iron Slabs from a single Iron Bar by using a Forge to transform iron ore into iron.

If there is a demand for more Iron Rods, each Iron Slab can then be further processed into four Iron Rods.Iron Slabs are essential ingredients in a variety of crafting recipes, including those for Diamond Mining Cells, Iron Furniture, and several distinct types of Iron Building Blocks (as of R26 in December 2015).

Iron Slabs can be positioned anywhere in the world and can be turned in any direction. They may also be presented in flower pots, as well as wood planters and other types of planters.

Steel Slab is described as a semi-finished steel product that is occasionally produced by processing ingots using a continuous casting method. The final product of rolling ingots in a rolling mill, steel slab is the end result of the rolling process.

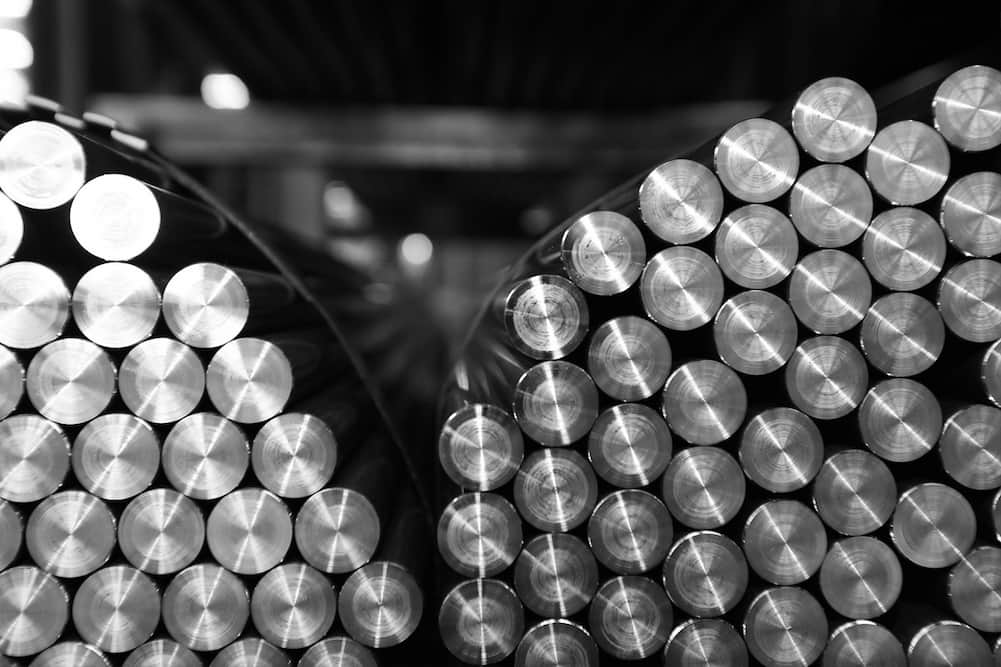

Slabs of steel, which have cross-sections in the shape of rectangles, are the raw material for the production of flat products like steel plates and hot rolled coils. Slabs are utilised as the starting metal in this process. Slabs are often manufactured in a flat form and rectangular shape, with thicknesses ranging from 160 millimetres and upwards. Steel Slab is utilised in a wide variety of sectors today, which is astounding.

steel slab size

Steel can produce various finished products such as rebars, wires, stainless steels, etc. in a variety of sizes from its semi-finished products like as billets, slabs, and bloom, which come in a variety of varieties depending on the amount of carbon involved.

A slab is a rectangular-cross-section length of metal. The slab is produced either directly by continuous casting or indirectly through rolling an ingot on a slabbing mill. Slabs are typically processed further through flat rolling, skelping, and pipe rolling. Sheet metal, plates, strip metal, pipes, and tubes are common end products. Slab is mostly made in blast furnaces. One reason to preferentially create slab via the BF technique is to obtain good quality.

Steel bars used in construction come in sizes such as 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm, 45mm, 50mm, 60mm, and so on, and higher dia/size steel bars such as 75mm, 90mm, and 100mm are also customisable by various steel companies.

Steel bars used in building construction are 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, and 25mm in diameter. Steel bars with diameters of 6mm and 8mm are used for stirrup formation, steel bars with diameters of 8mm to 12mm are used in slabs, and steel bars with diameters of 12mm to 25mm are used for beams and columns.

The diameter/size of steel bars used in slabs is determined by the design structure, one way slab, two way slab, and flat slab. Steel bars with diameters of 8mm, 10mm, and 12mm are commonly used in slabs.

The diameter/size of steel bar required for column and beam is determined by the design structure, the load operating on it, and the span between two supports. However, steel bars with a size/diameter of 12mm to 25mm are generally required for beam and column. Steel bar with a diameter of 32mm can sometimes be provided for raft foundations.

steel slab vs billet

Today’s businesses are built on steel, one of the most significant metals that may be used in many different forms, including slab, billet, bloom, etc. A piece of metal that is less than 36 inches in length and has a cross-section that is either round or square is called a billet (230 cm2).

Billets can be produced directly through processes such as continuous casting or extrusion, or indirectly through the process of hot rolling an ingot or bloom. Additional processing steps include profile rolling and drawing on the billets. Bar stock and wire are both included in the final products.

The production of short circular tubes as billets can also be accomplished using centrifugal casting. This is typically done in order to establish a precise metallurgical structure.

They are frequently put to use as cylinder sleeves, in which case both the inner and the outer diameters are ground and the length is machined. Because their dimensions do not change greatly, casting goods that contain them are not always considered to be in the semi-finished stage.

A pure copper bar of approximately 8 inches (200 millimetres) in diameter and 30 feet (9.1 metres) in length is referred to as a billet in the process of producing copper.

A piece of metal that is cut into a rectangular shape along its length is called a slab. Either directly via continuous casting or indirectly by rolling an ingot on a slabbing mill will result in the creation of the slab. Flat rolling, skelping, and pipe rolling are the typical subsequent processes that are performed on slabs.

Sheet metal, plates, strip metal, pipes, and tubes are all common forms of the product’s ultimate iteration. The blast furnace production method is typically used to create slab. To provide a product of good quality, it is recommended that slab be produced through the BF approach wherever possible.

slab steel

We produce slab that is of the highest caliber and adheres to international requirements. House construction made possible thanks to the usage of steel bar in the form of slab beam and column.

The column is the flexural member of a concrete structure, while the slab and beam are the compressive members. Concrete can be made more resistant to tensional pressures by including reinforcing steel bars into the mix.

there are many different sizes and diameters of steel bar that are used in construction, including 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm, 45mm, 50mm, and so on.

Higher dai/sizes of steel bar, such as 60mm, 75mm, 90mm, and 100mm, can be customised by various steel companies to meet specific customer requirements and are then made available for purchase. Because it is so thin, it is often referred to as “pencil rod,” and it takes on the appearance of a pencil. 5mm Steel bar are also available, but they are not used for structural work.

Steel bars of varying sizes and diameters are utilised in the construction of building structures such as columns, beams, and slabs. These dimensions are determined by the design structure, the distance that separates columns, and the load that is placed on each column.

However, in general, steel bars with a size or diameter of 8 millimetres, 10 millimetres, or 12 millimetres are used in slabs; bars with a size or diameter of 12 millimetres, 16 millimetres, 20 millimetres, or 25 millimetres are used for columns and beams; and bars with a higher dia/size, such as 32 millimetres, 40 millimetres, 45 millimetres, or 50 millimeteres.

Steel appears to be intertwined with every facet of our existence. Steel, for example, is widely used in the construction of several things other than houses and hospitals, such as highways and bridges. It is also widely used in the production of various types of vehicles.

Steel is a necessary element in the transition to renewable energy sources. Wind turbines and solar panels, as well as dams and electric vehicles, fall in that category.

Steel will also play a significant role in the impending energy revolution. Steel consumption has tripled in last four decades, and this trend is likely to continue as economies around the world develop and urbanize, becoming much more consumer-oriented and investing in their own facilities and infrastructures.

We are the only place in the world where this metal, its compounds, and the semi- and finished products derived from them would be found. We have become the supplier and provider that we are today is the result of our many years of professional experience. If you want to make a purchase or if you need any help and support, simply fill out the online form.

Every one of our products is available in a variety of surface treatments and dimensions, and we can customize any of our existing inventory to your specific needs using our bespoke cutting service. To ensure that you get precisely what you need to finish your project, we provide you with a variety of presentation choices to choose from. We do not compromise on quality, and as a result, we offer a wide range of metal sheets.

Your comment submitted.