Choosing the Right Material for Your Business In the world of metal fabrication and manufacturing, two materials stand out when it comes to sheet metal: aluminum and steel. Both materials possess unique characteristics that make them suitable for various applications. In this article, we will explore the differences between aluminum and steel sheet metal and help you determine which material is the right choice for your business. Strength and Durability: When it comes to strength and durability, steel has long been the go-to material. It is renowned for its high tensile and impact strength, making it ideal for applications that require heavy-duty performance and structural integrity. Steel sheet metal can withstand heavy loads and extreme weather conditions, making it suitable for construction, automotive, and other industries where strength is a top priority. On the other hand, aluminum offers an impressive strength-to-weight ratio.

.

Although aluminum is not as strong as steel, it compensates with its lightweight nature. This makes aluminum sheet metal suitable for applications that require lightweight materials, such as aerospace and transportation industries. Aluminum is also highly resistant to corrosion, making it an excellent choice for outdoor applications. Cost and Affordability: Cost is a crucial factor in any business decision. When comparing aluminum and steel sheet metal, it is important to consider both the upfront and long-term costs. Steel sheet metal tends to be more affordable than aluminum, particularly in terms of raw material costs. However, steel is denser than aluminum, resulting in higher shipping and transportation costs. Additionally, steel requires special coatings to protect against corrosion, which adds to its overall cost. On the other hand, aluminum sheet metal is generally more expensive upfront. However, its corrosion resistance eliminates the need for additional coatings, reducing long-term maintenance costs. Aluminum’s light weight also contributes to lower transportation and installation costs.

Although aluminum is not as strong as steel, it compensates with its lightweight nature. This makes aluminum sheet metal suitable for applications that require lightweight materials, such as aerospace and transportation industries. Aluminum is also highly resistant to corrosion, making it an excellent choice for outdoor applications. Cost and Affordability: Cost is a crucial factor in any business decision. When comparing aluminum and steel sheet metal, it is important to consider both the upfront and long-term costs. Steel sheet metal tends to be more affordable than aluminum, particularly in terms of raw material costs. However, steel is denser than aluminum, resulting in higher shipping and transportation costs. Additionally, steel requires special coatings to protect against corrosion, which adds to its overall cost. On the other hand, aluminum sheet metal is generally more expensive upfront. However, its corrosion resistance eliminates the need for additional coatings, reducing long-term maintenance costs. Aluminum’s light weight also contributes to lower transportation and installation costs.

..

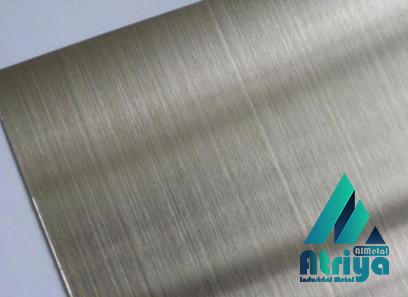

Appearance and Aesthetic Appeal: While functionality and durability are significant factors, the aesthetic appeal of sheet metal cannot be ignored. Steel sheet metal is known for its traditional and industrial look. Its strength and durability are often associated with a sense of ruggedness and reliability. As a result, steel is commonly used in industries where a robust appearance is desired, such as manufacturing and construction. Aluminum sheet metal, on the other hand, offers a sleek and modern appearance. Its lightweight and reflective surface make it popular in industries where aesthetics play a crucial role, such as automotive, architecture, and interior design. Environmental Impact: In today’s environmentally conscious world, businesses are increasingly seeking sustainable options.

Appearance and Aesthetic Appeal: While functionality and durability are significant factors, the aesthetic appeal of sheet metal cannot be ignored. Steel sheet metal is known for its traditional and industrial look. Its strength and durability are often associated with a sense of ruggedness and reliability. As a result, steel is commonly used in industries where a robust appearance is desired, such as manufacturing and construction. Aluminum sheet metal, on the other hand, offers a sleek and modern appearance. Its lightweight and reflective surface make it popular in industries where aesthetics play a crucial role, such as automotive, architecture, and interior design. Environmental Impact: In today’s environmentally conscious world, businesses are increasingly seeking sustainable options.

…

Both aluminum and steel are recyclable materials, but aluminum is renowned for its high recycling rate. Aluminum can be recycled repeatedly without any degradation in quality, making it an environmentally friendly choice. Furthermore, the energy required to recycle aluminum is significantly lower than that of steel, contributing to its lower carbon footprint. Conclusion: Choosing between aluminum and steel sheet metal depends on various factors specific to your business needs. Steel offers strength and durability at an affordable cost but requires additional coatings to protect against corrosion. Aluminum, although more expensive upfront, is lightweight, corrosion-resistant, and has a modern aesthetic appeal. Ultimately, the decision should be based on the specific requirements of your industry, weighing factors such as strength, cost, appearance, and environmental impact.

Both aluminum and steel are recyclable materials, but aluminum is renowned for its high recycling rate. Aluminum can be recycled repeatedly without any degradation in quality, making it an environmentally friendly choice. Furthermore, the energy required to recycle aluminum is significantly lower than that of steel, contributing to its lower carbon footprint. Conclusion: Choosing between aluminum and steel sheet metal depends on various factors specific to your business needs. Steel offers strength and durability at an affordable cost but requires additional coatings to protect against corrosion. Aluminum, although more expensive upfront, is lightweight, corrosion-resistant, and has a modern aesthetic appeal. Ultimately, the decision should be based on the specific requirements of your industry, weighing factors such as strength, cost, appearance, and environmental impact.

Your comment submitted.