Price of One Way Slab Steel: The most influential factors in the price of each slab branch are its thickness, length and width. Slabs are usually produced in lengths of 4, 6, 10 and 12 meters and thickness of 30 to 300 mm. The price of this product is announced in kilograms. slab steel use and slab steel application: Slabs are used to make heavy industrial machinery; But it is mostly used in making steel sheets in the form of coils or sheets used as a raw material for making some steel other products such as pipes. Steel slabs are also used to make quadrilaterals and corrugated sheets.

How to Calculate Quantity of Steel in One Way Slab?

The amount of steel used in one-sided slab will be less compared to two-sided slab. The amount of load and pressure applied to a slab will be one-way. Due to the fact that less steel is used in the construction of one-sided slabs, we will face an increase in the depth of the slab. Composite concrete slab or steel deck is another slab used in the construction industry. This type of slab is placed on a steel floor and its function is just like the function of a frame. The construction of this type of slab depends on the thickness of the steel floor. Calculation of the one-way slab steel quantity would be done pursuant to its supporting status. The one-way slab is leaning on two beams and to the columns of the any constructions. We use Bars in the Tension zone of the slab which called Bent up bars. Actually, in the slab, we have two different bars which included main bars and distribution bars.Presumably on one way slap with length of 5m or 2m width as clear span Main bar become 12mm diameter and 100 mm spacing. Therefore, Distribution bars with 8mm diameter and 125 spacing. So clear cover would be 25 mm and the Thickness of the Slap will be 150mm

The amount of steel used in one-sided slab will be less compared to two-sided slab. The amount of load and pressure applied to a slab will be one-way. Due to the fact that less steel is used in the construction of one-sided slabs, we will face an increase in the depth of the slab. Composite concrete slab or steel deck is another slab used in the construction industry. This type of slab is placed on a steel floor and its function is just like the function of a frame. The construction of this type of slab depends on the thickness of the steel floor. Calculation of the one-way slab steel quantity would be done pursuant to its supporting status. The one-way slab is leaning on two beams and to the columns of the any constructions. We use Bars in the Tension zone of the slab which called Bent up bars. Actually, in the slab, we have two different bars which included main bars and distribution bars.Presumably on one way slap with length of 5m or 2m width as clear span Main bar become 12mm diameter and 100 mm spacing. Therefore, Distribution bars with 8mm diameter and 125 spacing. So clear cover would be 25 mm and the Thickness of the Slap will be 150mm

The Advantages of One Way Slab Steel

In the production of slabs, the casting process is used, which has advantages. These advantages are: Earthquake resistant due to weight loss, Consumption of consumables, Flexural behavior and high shear strength, Acceptable creep, High fire resistance, Shorter build time (20% to 40%), Longer and useful life of the building, Fairly good sound insulation, Reduce shipping costs.

In the production of slabs, the casting process is used, which has advantages. These advantages are: Earthquake resistant due to weight loss, Consumption of consumables, Flexural behavior and high shear strength, Acceptable creep, High fire resistance, Shorter build time (20% to 40%), Longer and useful life of the building, Fairly good sound insulation, Reduce shipping costs.

In one way slab load won’t be transferred to the beams of shorter size.

Just one direction would provide for the basic reinforcement when you use One way slabs.

One way slabs actually is being designed to transfer the loads to opposite side of supporting walls

Steel slab is very useful in the construction of earthquake-proof structures. These one-sided signs also show high resistance to heat. One-sided steel slab is used in cases where the block joist roof can not be used. One-sided steel slab is cheaper and also easier to implement than block joists. One-sided steel slabs are not suitable for buildings with steel structures.

One Way Slab Steel Production

There are three main methods for producing slabs, which are mentioned below:

There are three main methods for producing slabs, which are mentioned below:

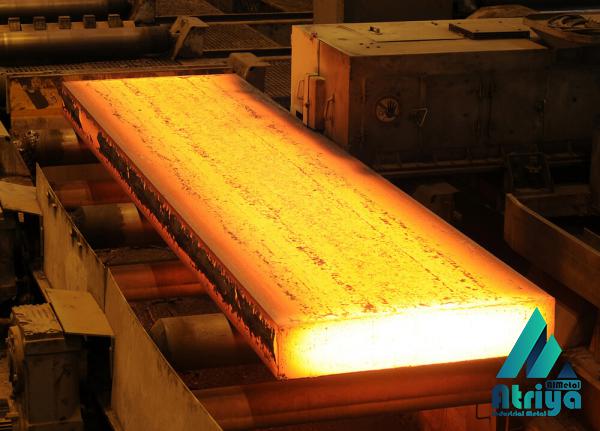

- Blast furnace method: Blast furnace method is a traditional method that uses indirect reduction to produce slabs. Given that If has high quality coal resources, this method is a practical method. First, iron ore with lime and coke is brought into a blast furnace and crude iron (molten cast iron) is extracted. To remove impurities from molten steel obtained from crude iron, crude steel is obtained by removing carbon and adding oxygen. Then, in a continuous casting unit, the melt is poured into the mold. By removing the product from the mold and spraying cold water, the slab cools and turns into a frozen ingot. Finally, with different sections, the desired lengths of the slab can be obtained.

- Electric furnace: The second method of steel production is the use of electric furnaces and remelting of scrap iron and steel in which iron baskets are poured into the furnace. Due to the scarcity of scrap resources in the world and its increase in price in recent years, in this method, in addition to waste, sponge iron is also used to melt in the furnace. Therefore, at the same time as melting scrap iron, a mixture of sponge iron and slag-making materials such as coke, bentonite, lime and other additives is added to the melt from the top of the furnace. Finally, it is produced by homogenizing molten steel. In the casting unit, the molten steel is cast in the form of hydrophilic copper and then sprayed on the cold steel to form frozen steel ingots.

- Induction: Induction furnace method has a high cost due to the use of electricity, electrodes and additives.

Hello good time

I bought pistachio product from this site.

It is very tasty and of high quality.

Pistachio is also a dried fruit that has positive effects on human health.