Introducing black steel sheet + the best purchase price

People first learned how to work with iron some 6,000 years ago

The ultra-common element wasn’t used in its most crucial function, the production of steel, until a few thousand years later

Steel is used in hand tools, large construction equipment, home appliances, and applications involving mechanics and electricity

Making that decision could be challenging because of the large selection available

Steel is an iron alloy, which implies that iron is its main constituent

One or more alloying metals are then added to the iron to create new materials with properties that are different from those of iron alone

Steel

There are four main categories, but within each of those categories, there are several subcategories, each of which serves a particular purpose

When combined with other elements, iron acquires new properties, and these properties can change based on how the metal is heated and cooled

The strong demand and expanding uses across various industries have caused the sheet metal production process to advance and improve over time

Sheet metal fabrication has developed into a type of art requiring the highest level of craftsmanship because of its many distinct techniques

The manufacture of precision sheet metal is one of the most widely used manufacturing techniques today

The numerous technical developments we’ve witnessed in industries like aircraft, electronics, medical, transportation, consumer electronics, and more all depend on sheet metal production

In reality, sheet metal fabrication is used in practically every industry

Price list for steel sheets

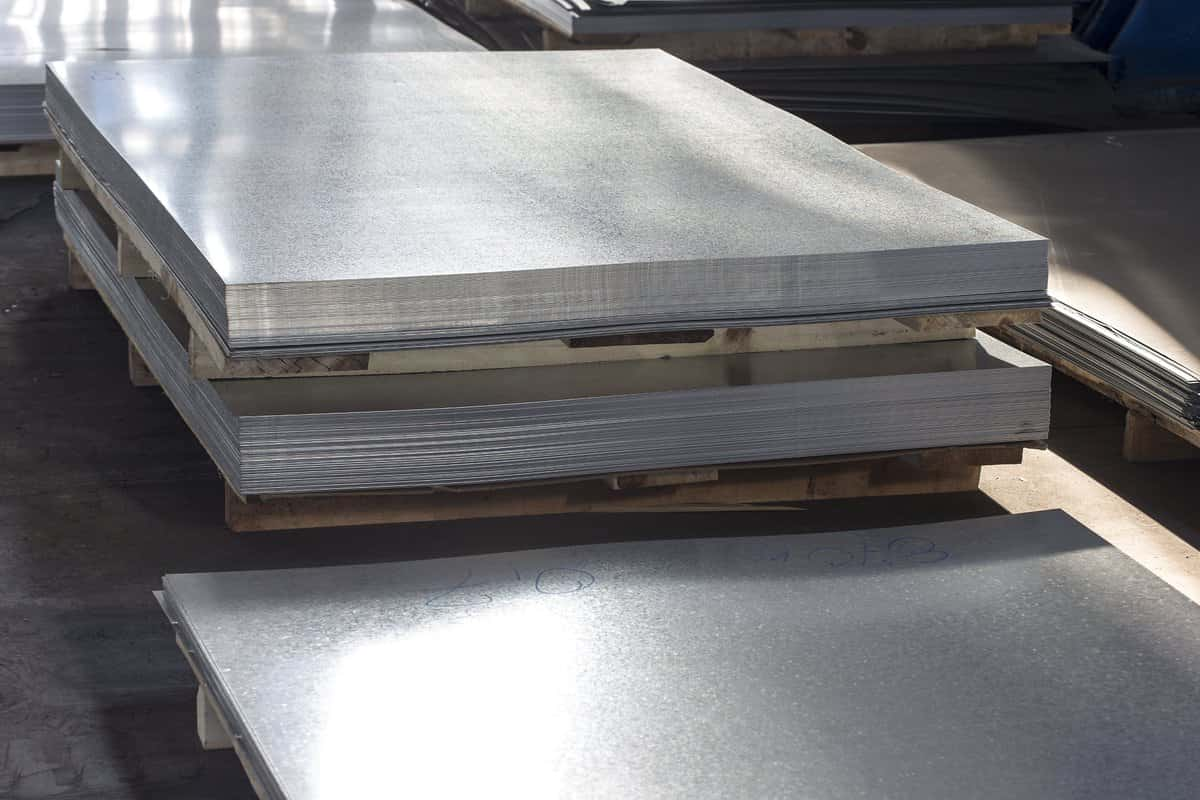

Black Steel Sheet Example

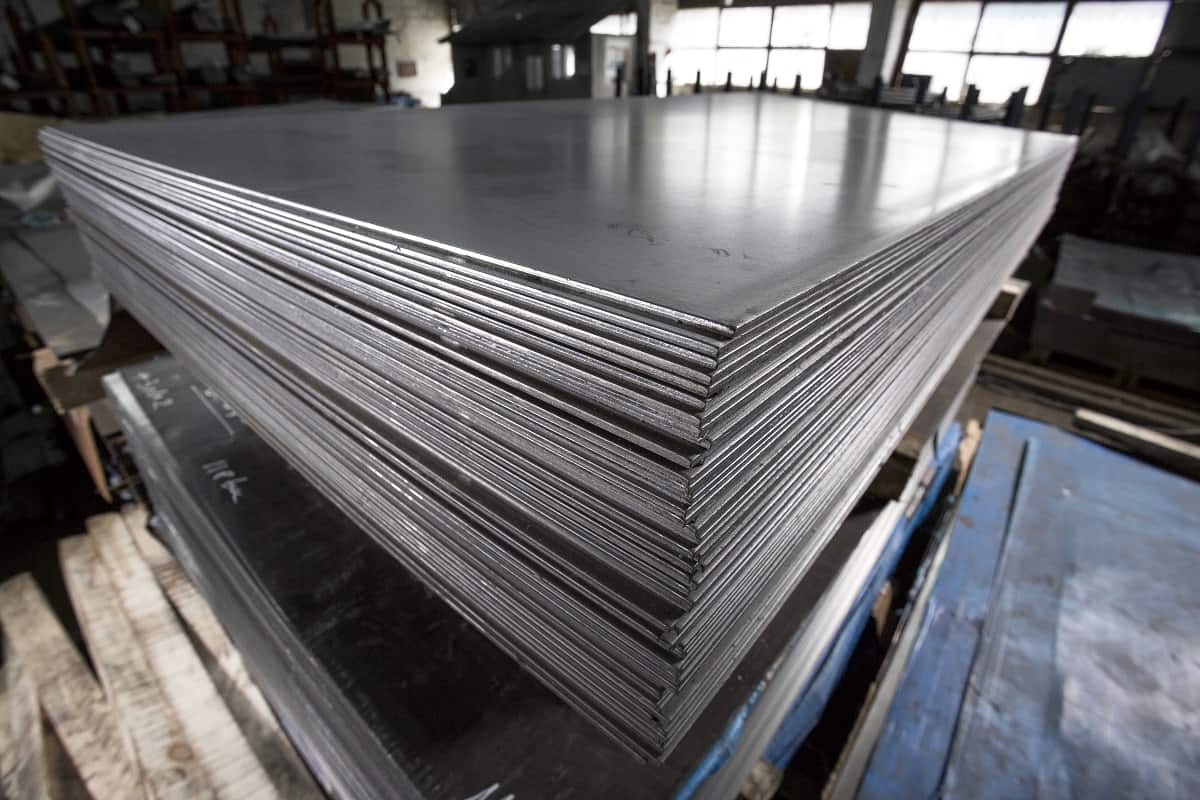

Metal that has been industrially processed into thin, flat pieces is called sheet metal

The following list of sheet metal samples will be provided

One of the basic materials used in metalworking is sheet metal, which can be bent and cut into a wide range of shapes

There are six main varieties of sheet metal, each with special benefits:

Steel alloy

Stainless steel

Steel carbon

Steel tool

Galvanized steel

Aluminum

Extremely thin sheets are referred to as foil or leaf, whereas sections thicker than 6 mm (0

25 in) are referred to as plate, such as plate steel, a type of structural steel

Thicknesses can vary greatly There are flat pieces of sheet metal and coiled strips available

A roll slitter is used to cut a continuous sheet of metal into coils

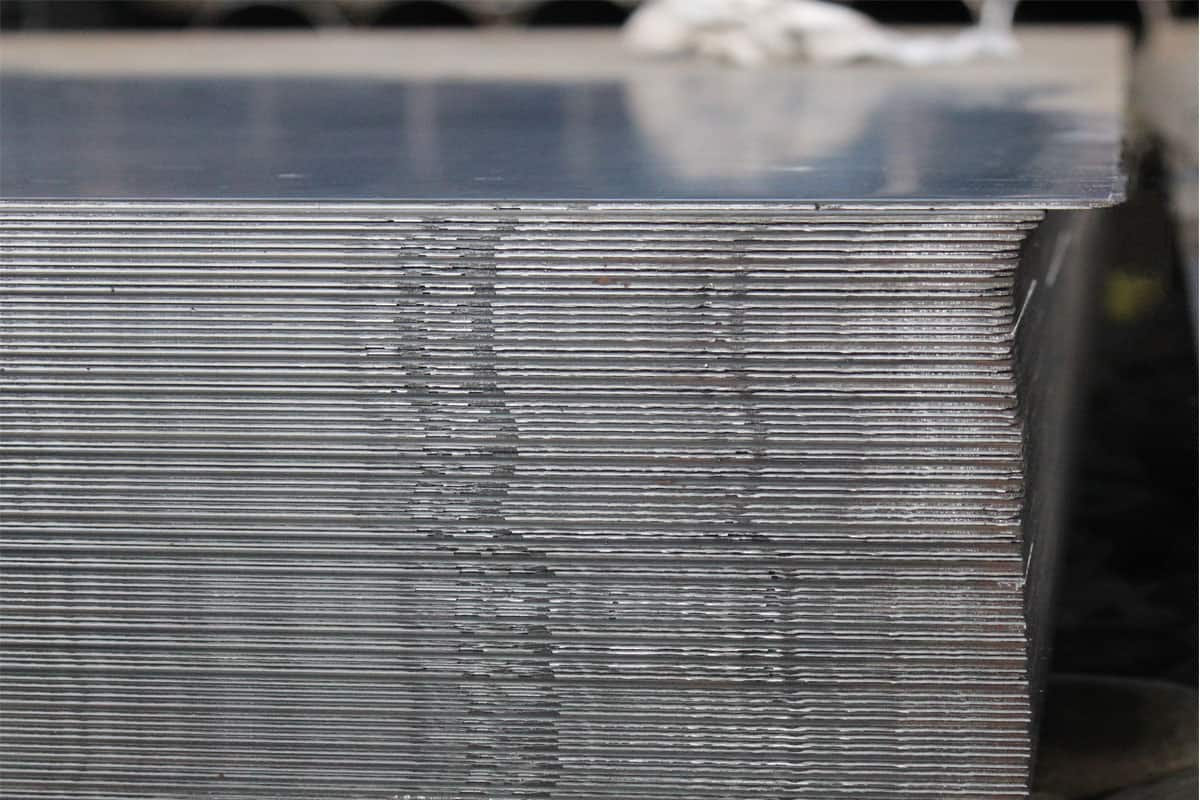

The majority of the world regularly specifies sheet metal thickness in millimeters

In the US, the gauge—a conventional, non-linear measure—is frequently used to specify sheet metal thickness

The metal is thinner the higher the gauge number

Steel Products Stainless

Steel sheet metal in common applications ranges in gauge from 30 to around 7

Compared to nonferrous metals like aluminum or copper, ferrous (metals based on iron) metals have different gauges

For instance, the weight of copper in a square foot of material is measured in ounces, or copper thickness

For best results, sheet metal parts must retain a consistent thickness

Sheet metal can be produced from a wide variety of metals, including aluminum, brass, copper, steel, tin, nickel, and titanium

Silver, gold, and platinum are significant sheet metals for decorative applications (platinum sheet metal is also utilized as a catalyst)

Equipment for kitchens and restaurants, elevators, doors, boats, car bodies, irrigation and drainage systems, guardrails, brackets, mailboxes, siding, roofing, gutters, electronics enclosures, trim, tanks, drawers, ventilation systems, hoods, cutlery, pipes, cabinets, containment systems, and other items are frequently made from sheet metal

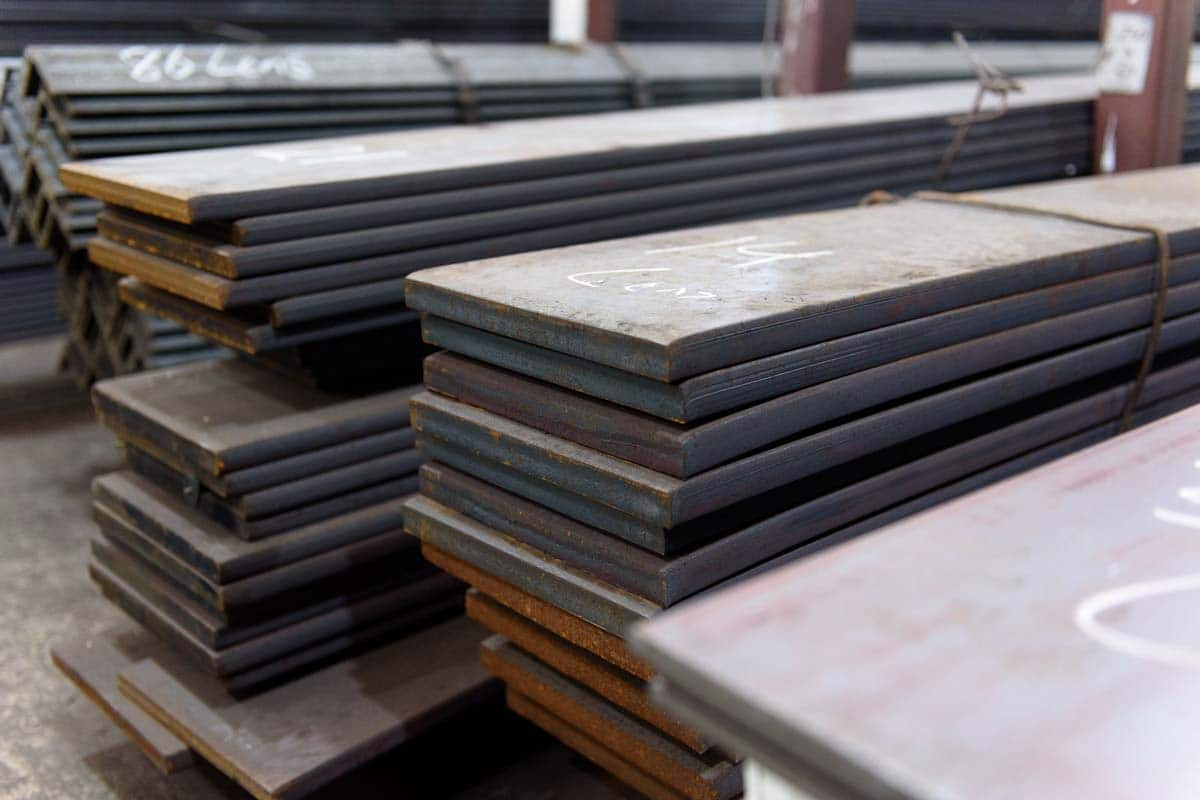

Rolled Steel Products

Black Steel Sheet Name

Black steel sheets are a type of material with high carbon content, and they get their name from their somewhat bluish black hue

The creation of items out of sheet metal is known as sheet metal fabrication

Numerous sectors all around the world depend largely on the manufacturing of sheet metal

For individuals involved in sheet metal fabrication, the creation of unique parts through sheet metal fabrication in developing nations like India and China has generated enormous opportunities

The strong demand and expanding uses across various industries have caused the sheet metal production process to advance and improve over time

Sheet metal fabrication has developed into a type of art requiring the highest level of craftsmanship because of its many distinct techniques

The manufacture of precision sheet metal is one of the most widely used manufacturing techniques today

The numerous technical developments we’ve witnessed in industries like aircraft, electronics, medical, transportation, consumer electronics, and more all depend on sheet metal production

In reality, sheet metal fabrication is used in practically every industry

Methods and Supplies Used in the Fabrication of Sheet Metal Cutting, forging, rolling, bending, assembling, engineering, welding, braking, powder coating, stamping, turret, and laser automation, riveting, punching, sub-contract manufacturing, prototyping, machine design, and technical drawing are all sheet metal fabrication processes and techniques

These sheet metal production procedures have a very low tolerance for error and demand high precision from expert workers

The fabrication of sheet metal is a crucial component of manufacturing, used in anything from massive structural projects and construction machinery to complex telephones and electronics

The materials used to fabricate sheet metal range greatly

All of the attributes that are frequently sought in metals used in the manufacture of sheet metal include strength, conductivity, hardness, flexibility, and resistance to corrosion

Black Steel Sheet Quotes

The end result of the casting process is a black sheet

It gets its name from its hue, and because of the features, it has, its utilization area is very broad

It has some drawbacks in addition to its benefits over competing products

What is Black Sheet? The flat steels made from the subsequent rolling of casting-method products are referred to as “black sheet

” Models made of mild steel are produced by hot rolling

In other words, the steel is first heated above the temperature at which it crystallizes

Then, parallel rollers are used to roll the material

At this point, the heated steel’s simpler shape provides a significant benefit

This benefit allows you the ability to produce items with the correct thickness and dimensions

At this point in the black sheet manufacture, it is crucial that there are no delays

What characteristics do black sheets have? Mild steel is produced in an innovative manner

As a result, it has various characteristics

The following is a list of the exceptional qualities of this unique product: It can be used for specialized manufacturing

The desired proportions can be achieved thanks to hot rolling

It can be molded easily

The casting procedure results in its production

It possesses considerable strength

It can be welded

Because it is simple to weld and shape, its application range is very broad

The general characteristics of mild steel are described here

The product’s thickness and form can affect how strong it is and how long it lasts

The tolerances for mild steel thickness range from 1

5 mm to 20 mm

Black Steel Sheet Uses

Sheet metal is metal that has undergone industrial processing to create thin, flat pieces

Sheet metal is one of the fundamental components used in metalworking, and it may be bent and cut into a variety of shapes

Foil and leaf are terms for extremely thin sheets, whereas plate, which includes structural steel plate that is thicker than 6 mm (0

25 in), is used to describe sections that are thicker than that

There are many different thicknesses

Both coiled strips and flat sheet metal are readily available

A continuous metal sheet is sliced into coils using a roll slitter

Millimeters are frequently used to specify sheet metal thickness

In the US, gauge, a non-linear metric, is used to determine sheet metal thickness

Higher gauge translates to thinner metal

The majority of steel sheet is 30 to 7 gauge

Metals made of iron have different gauges than metals made of aluminum or copper

The calculation of copper per square foot uses either ounces or copper thickness

It is preferable to have uniform sheet metal thickness

Numerous metals, including aluminum, brass, copper, steel, tin, nickel, and titanium, can be used to create sheet metal

Among the important sheet metals for ornamental applications are silver, gold, and platinum (platinum sheet metal is also utilized as a catalyst)

Among other things, sheet metal is used to make the bodies of cars, trucks, and lorries, as well as big appliances, airplane wings, tinplate for tin cans, and roofing for buildings

Iron sheet metal, laminated steel cores, and other high-permeability materials are used in transformers and other electrical equipment

Cavalry plate armor used to be made of sheet metal

Black Steel Sheet By Color

Because there is so much carbon in this type of carbon steel, black steel sheets have a bluish-black color

It is possible to produce sheet metal pieces out of a variety of metals and metal alloys

The selection of materials is based on the demands of the application, and considerations for material selection include:

Formability

Weldability

Corrosion Resistance

Resistance

Strength

Weight

Cost

Stainless steel products is a common type of sheet metal

In the manufacturing of sheet metal, two types of stainless steel are used: stand and spring-like

Any of the 300 series sheets of steel are the most often used variety of standard stainless, and they can all be non-magnetic

It doesn’t need hot work or any other type of stress release during production

The stainless steel type with the highest resistance to corrosion, Grade 316, also retains its strength at high temperatures

The most popular grade, Grade 304, has good formability and weldability while having a somewhat lower level of corrosion resistance

Black Steel Sheet Cut To Size

Any one of a wide range of metals is used to make sheet metal

Using a method that yields uniform pieces with predetermined thicknesses, your material of choice is shaped into thin sheets

Even though steel, particularly stainless or galvanized steel, is perhaps the most common type of sheet metal used in industrial applications, other metals, such as:

Brass

Copper

Aluminum

Tin

Titanium

Nickel

Platinum

Gold

Silver

Remember that the characteristics of certain metals can have a direct impact on your project

In other words, when it comes to qualities like strength and durability, not all metals are created equal

Select wisely

Four things to think about when choosing sheet metal sizes When it comes to sheet metal scaling, there are various things to keep in mind

These consist of:

Gauge

Thickness

Weight

Size specifications

GAUGE

The United States measures sheet metal thickness in gauges, but the majority of the rest of the world does it in millimeters

The sheet is thinner the higher the gauge number

In contrast, the thickness of the sheet increases with a smaller gauge number

THICKNESS

The thickness of sheet metal should be taken into account due to both the material’s cost and the labor-intensiveness of cutting the sheet

Not to mention the thickness of the material required for any bends

WEIGHT

Each sheet of a particular gauge has a particular weight

Pounds per square foot is the unit of weight measurement in the United States

The unit of weight in Europe and many other regions of the world is kilograms per square meter

SIZE SPECIFICATIONS

Standard sheet metal sizes come in a range, including: 36” x 96” 36” x 120” 36” x 144” 48” x 96” 48” x 120” 48” x 144”

Two well-known examples of adaptable metals are iron and carbon, which are the basic building blocks of a large amount of what we see in modern cities, including the infrastructure for telecommunications and transportation networks

Metals that have been around for a long time include iron and carbon

Despite the development of new ways to combine materials, steel has been used for a very long time, and it is not anticipated that this will change for a very long time

Metals like steel have been used for a very long period

We are the global supplier and provider of this priceless metal, as well as its derivatives and the finished and semi-finished goods made from them

Items made from it that have been completed are also included in this category

Our extensive professional expertise throughout the years has helped us become the supplier and provider that we are today

Filling out the inquiry form we’ve provided is all you need to do in order to make a purchase or request assistance