Hematite is an iron oxide mineral that is found in various colors, including metallic black, gray, brown, and red iron ores. It is the most abundant iron-bearing mineral and is highly valued for its high iron content and extensive use in the steel industry. Hematite iron ore is known for its dense nature, which plays a crucial role in various aspects of ore processing and handling. Bulk density refers to the mass (weight) of a specific volume of material. In the context of hematite iron ore, bulk density refers to the mass of the ore particles (solid phase) excluding the void spaces between them (pore space). The bulk density of hematite iron ore is typically around 5-6 metric tons per cubic meter, depending on the specific gravity of the mineral. The bulk density of hematite iron ore is influenced by various factors, including the composition of the ore, particle size distribution, moisture content, and compaction state. These factors can affect the porosity and packing arrangement of the ore particles, consequently impacting the bulk density.

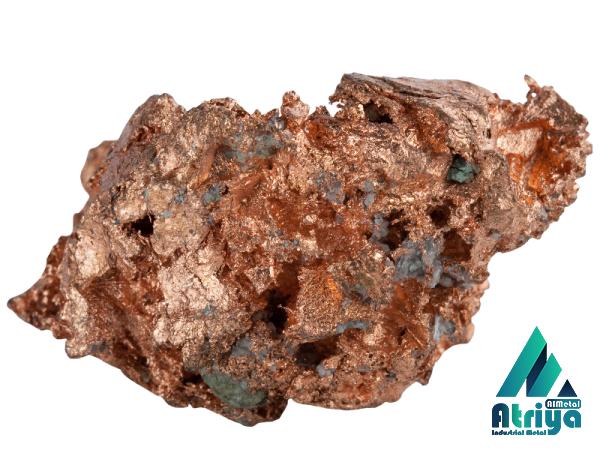

iron

The composition of hematite iron ore can vary, with different ores having different elemental and mineralogical compositions. However, the main component is iron oxide (Fe2O3). Other elements such as silica (SiO2), alumina (Al2O3), and trace elements might also be present, depending on the specific ore deposit. The presence of impurities can affect the bulk density of the ore, as impurities often have different densities than hematite. Particle size distribution plays a significant role in determining the bulk density of hematite iron ore. The particle size distribution refers to the range of particle sizes present in the ore. In general, a wider particle size distribution leads to a lower bulk density, as there is a greater variation in particle size and more pore spaces between the particles. Conversely, a narrower particle size distribution results in a higher bulk density, as there is less variation in particle size and fewer pore spaces. Moisture content is another factor that affects the bulk density of hematite iron ore. Moisture refers to the amount of water present in the ore, either as free water or bound water. The presence of moisture can increase the porosity of the ore, thereby reducing the bulk density.

The composition of hematite iron ore can vary, with different ores having different elemental and mineralogical compositions. However, the main component is iron oxide (Fe2O3). Other elements such as silica (SiO2), alumina (Al2O3), and trace elements might also be present, depending on the specific ore deposit. The presence of impurities can affect the bulk density of the ore, as impurities often have different densities than hematite. Particle size distribution plays a significant role in determining the bulk density of hematite iron ore. The particle size distribution refers to the range of particle sizes present in the ore. In general, a wider particle size distribution leads to a lower bulk density, as there is a greater variation in particle size and more pore spaces between the particles. Conversely, a narrower particle size distribution results in a higher bulk density, as there is less variation in particle size and fewer pore spaces. Moisture content is another factor that affects the bulk density of hematite iron ore. Moisture refers to the amount of water present in the ore, either as free water or bound water. The presence of moisture can increase the porosity of the ore, thereby reducing the bulk density.

Specifications of iron

Additionally, the moisture content can affect the cohesiveness and flow properties of the ore, which can impact the handling and transportability of the material. The compaction state of hematite iron ore is an important factor influencing its bulk density. The compaction state refers to the degree of compaction or packing arrangement of the ore particles. A highly compacted ore will have a higher bulk density, as there are fewer pore spaces between the particles. Conversely, a loosely packed or unconsolidated ore will have a lower bulk density, as there are more pore spaces. The bulk density of hematite iron ore has several implications in various stages of ore processing and handling. Firstly, it affects the economic viability of mining operations, as it determines the volume of material that can be extracted and transported. Higher bulk density ore allows for greater extraction efficiency and reduced transportation costs. Secondly, the bulk density influences the efficiency of ore beneficiation processes. Beneficiation involves separating the iron ore from impurities through processes such as crushing, screening, and magnetic separation.

Additionally, the moisture content can affect the cohesiveness and flow properties of the ore, which can impact the handling and transportability of the material. The compaction state of hematite iron ore is an important factor influencing its bulk density. The compaction state refers to the degree of compaction or packing arrangement of the ore particles. A highly compacted ore will have a higher bulk density, as there are fewer pore spaces between the particles. Conversely, a loosely packed or unconsolidated ore will have a lower bulk density, as there are more pore spaces. The bulk density of hematite iron ore has several implications in various stages of ore processing and handling. Firstly, it affects the economic viability of mining operations, as it determines the volume of material that can be extracted and transported. Higher bulk density ore allows for greater extraction efficiency and reduced transportation costs. Secondly, the bulk density influences the efficiency of ore beneficiation processes. Beneficiation involves separating the iron ore from impurities through processes such as crushing, screening, and magnetic separation.

buy iron

The bulk density of hematite iron ore affects the separation efficiency, as it determines the amount of gangue (non-valuable material) that needs to be removed. Higher bulk density ore requires less processing and results in a higher yield of iron concentrate. Thirdly, the bulk density of hematite iron ore affects the handling and storage of the material. Bulk density is a crucial parameter in designing the infrastructure for ore handling and storage facilities, such as conveyors, stockpiles, and ship loading facilities. It determines the capacity and dimensions of these facilities, ensuring efficient material flow and minimizing operational costs. Furthermore, the bulk density of hematite iron ore impacts the transportation logistics. Transporting iron ore requires consideration of its bulk density to optimize cargo capacity and avoid overloading of vehicles or vessels. Bulk carriers, trains, and trucks have weight limits, and knowing the bulk density helps in planning and maximizing the utilization of these transportation modes. In conclusion, hematite iron ore is known for its dense nature, with a bulk density typically around 5-6 metric tons per cubic meter. The bulk density is influenced by various factors, including the composition of the ore, particle size distribution, moisture content, and compaction state. Understanding and controlling the bulk density of hematite iron ore is vital for efficient and cost-effective ore processing, handling, and transportation in the mining and steel industries.

The bulk density of hematite iron ore affects the separation efficiency, as it determines the amount of gangue (non-valuable material) that needs to be removed. Higher bulk density ore requires less processing and results in a higher yield of iron concentrate. Thirdly, the bulk density of hematite iron ore affects the handling and storage of the material. Bulk density is a crucial parameter in designing the infrastructure for ore handling and storage facilities, such as conveyors, stockpiles, and ship loading facilities. It determines the capacity and dimensions of these facilities, ensuring efficient material flow and minimizing operational costs. Furthermore, the bulk density of hematite iron ore impacts the transportation logistics. Transporting iron ore requires consideration of its bulk density to optimize cargo capacity and avoid overloading of vehicles or vessels. Bulk carriers, trains, and trucks have weight limits, and knowing the bulk density helps in planning and maximizing the utilization of these transportation modes. In conclusion, hematite iron ore is known for its dense nature, with a bulk density typically around 5-6 metric tons per cubic meter. The bulk density is influenced by various factors, including the composition of the ore, particle size distribution, moisture content, and compaction state. Understanding and controlling the bulk density of hematite iron ore is vital for efficient and cost-effective ore processing, handling, and transportation in the mining and steel industries.

Your comment submitted.