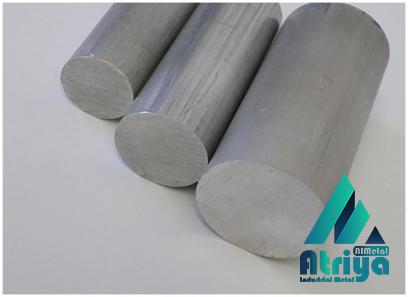

Cold Drawn Aluminium Bar: A Versatile Solution for Various Applications Aluminium, with its unique combination of lightness and strength, is one of the most widely used metals across industries. From aerospace to automotive, construction to electronics, aluminium finds its way into a multitude of applications. One form of aluminium that is gaining popularity in recent years is cold drawn aluminium bar. Cold drawn aluminium bar is a versatile product that offers several advantages over other forms of aluminium. It is manufactured by the process of cold drawing, where a round aluminium billet is drawn through a series of dies at room temperature. This process imparts certain desirable properties to the bar, making it an ideal choice for various applications. One of the key advantages of cold drawn aluminium bar is its improved mechanical properties.

.

The process of cold drawing imparts a higher tensile strength and yield strength to the bar, making it stronger and more durable compared to other forms of aluminium. This makes it suitable for applications that require high strength and reliability, such as structural components in aerospace or heavy machinery. Furthermore, the cold drawing process also improves the surface finish of the aluminium bar. The resulting surface is smooth, precise, and free from defects, making it easier to machine and fabricate. This makes cold drawn aluminium bar an excellent choice for applications that require tight tolerances, such as precision components in the electronics or automotive industry. Another advantage of cold drawn aluminium bar is its improved dimensional accuracy.

The process of cold drawing imparts a higher tensile strength and yield strength to the bar, making it stronger and more durable compared to other forms of aluminium. This makes it suitable for applications that require high strength and reliability, such as structural components in aerospace or heavy machinery. Furthermore, the cold drawing process also improves the surface finish of the aluminium bar. The resulting surface is smooth, precise, and free from defects, making it easier to machine and fabricate. This makes cold drawn aluminium bar an excellent choice for applications that require tight tolerances, such as precision components in the electronics or automotive industry. Another advantage of cold drawn aluminium bar is its improved dimensional accuracy.

..

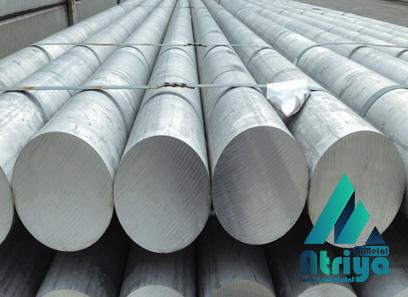

The cold drawing process ensures tight dimensional control, resulting in bars with consistent and precise dimensions. This is particularly crucial in applications where dimensional accuracy is crucial, such as in the manufacturing of extrusions or profiles. Moreover, cold drawn aluminium bar offers excellent corrosion resistance. Aluminium naturally forms a protective oxide layer on its surface, which helps to protect it from corrosion. The cold drawing process does not degrade this oxide layer and, in fact, enhances it. This makes cold drawn aluminium bar suitable for applications in corrosive environments, such as marine or chemical industries. Furthermore, the versatility of cold drawn aluminium bar extends to its wide range of available alloys.

The cold drawing process ensures tight dimensional control, resulting in bars with consistent and precise dimensions. This is particularly crucial in applications where dimensional accuracy is crucial, such as in the manufacturing of extrusions or profiles. Moreover, cold drawn aluminium bar offers excellent corrosion resistance. Aluminium naturally forms a protective oxide layer on its surface, which helps to protect it from corrosion. The cold drawing process does not degrade this oxide layer and, in fact, enhances it. This makes cold drawn aluminium bar suitable for applications in corrosive environments, such as marine or chemical industries. Furthermore, the versatility of cold drawn aluminium bar extends to its wide range of available alloys.

…

Aluminium alloys can be specifically tailored to meet the requirements of a particular application, such as high strength, better formability, or improved weldability. This allows manufacturers to select the most suitable alloy for their specific needs, ensuring optimal performance and cost-effectiveness. In conclusion, cold drawn aluminium bar is a versatile solution that offers several advantages for various applications. Its improved mechanical properties, surface finish, dimensional accuracy, corrosion resistance, and wide range of available alloys make it a preferred choice for industries such as aerospace, automotive, construction, electronics, and more. As the demand for lightweight, high-strength materials continues to grow, cold drawn aluminium bar is poised to play a significant role in meeting these needs.

Aluminium alloys can be specifically tailored to meet the requirements of a particular application, such as high strength, better formability, or improved weldability. This allows manufacturers to select the most suitable alloy for their specific needs, ensuring optimal performance and cost-effectiveness. In conclusion, cold drawn aluminium bar is a versatile solution that offers several advantages for various applications. Its improved mechanical properties, surface finish, dimensional accuracy, corrosion resistance, and wide range of available alloys make it a preferred choice for industries such as aerospace, automotive, construction, electronics, and more. As the demand for lightweight, high-strength materials continues to grow, cold drawn aluminium bar is poised to play a significant role in meeting these needs.

Your comment submitted.