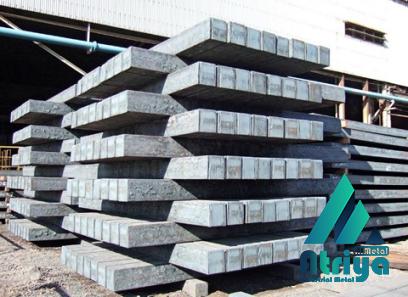

Understanding the Differences In the world of steel production and trading, LME Steel Billet types play a crucial role. The London Metal Exchange (LME) is a leading global marketplace for industrial metals, and steel billets are among the key products traded on this platform. Steel billets are essentially semi-finished products that are used as raw materials for various steel products. These billets are typically formed through casting molten steel into a rectangular shape, allowing for further processing and shaping into finished products like bars, rods, and wires. The LME provides a transparent and efficient marketplace for buyers and sellers to trade different types of steel billets. Understanding the different types of LME Steel Billets is essential for industry participants to make informed decisions and optimize their operations. Let’s take a closer look at some of these types: 1. Standard Billets: Standard Billets are the most commonly traded and widely recognized type of steel billet on the LME. These billets are produced using standard methods and have specific chemical compositions and dimensions. Standard Billets are sought after by buyers who require consistent quality and specifications.

.

2. Low-Alloy Billets: Low-Alloy Billets contain a lower percentage of alloying elements compared to standard billets. These billets are often used in applications where high strength and durability are required, such as in the automotive and construction industries. Low-Alloy Billets offer cost and weight savings without compromising on performance. 3. High-Carbon Billets: High-Carbon Billets, as the name suggests, have a higher carbon content compared to standard billets. The increased carbon content enhances the strength and hardness of the steel, making them suitable for applications that require high wear resistance. High-Carbon Billets are commonly used in the production of cutting tools, springs, and other components that undergo heavy wear and tear.

2. Low-Alloy Billets: Low-Alloy Billets contain a lower percentage of alloying elements compared to standard billets. These billets are often used in applications where high strength and durability are required, such as in the automotive and construction industries. Low-Alloy Billets offer cost and weight savings without compromising on performance. 3. High-Carbon Billets: High-Carbon Billets, as the name suggests, have a higher carbon content compared to standard billets. The increased carbon content enhances the strength and hardness of the steel, making them suitable for applications that require high wear resistance. High-Carbon Billets are commonly used in the production of cutting tools, springs, and other components that undergo heavy wear and tear.

..

4. Stainless Steel Billets: Stainless Steel Billets are primarily made of iron with significant amounts of chromium and other alloying elements. These billets offer excellent corrosion resistance, making them ideal for applications where exposure to moisture or aggressive environments is expected. Stainless Steel Billets find applications in industries like construction, marine, and food processing. 5. Rebar Billets: Rebar Billets are specifically designed for the production of reinforced steel bars (rebars). These billets have precise chemical compositions and mechanical properties to ensure the desired strength and ductility of rebars. Rebars are commonly used in construction to reinforce concrete structures, providing stability and durability.

4. Stainless Steel Billets: Stainless Steel Billets are primarily made of iron with significant amounts of chromium and other alloying elements. These billets offer excellent corrosion resistance, making them ideal for applications where exposure to moisture or aggressive environments is expected. Stainless Steel Billets find applications in industries like construction, marine, and food processing. 5. Rebar Billets: Rebar Billets are specifically designed for the production of reinforced steel bars (rebars). These billets have precise chemical compositions and mechanical properties to ensure the desired strength and ductility of rebars. Rebars are commonly used in construction to reinforce concrete structures, providing stability and durability.

…

Understanding the different types of LME Steel Billets allows participants in the industry to choose the appropriate billet for their specific requirements. Factors such as chemical composition, mechanical properties, and intended use play a significant role in determining the suitability of a particular billet type. The LME provides a centralized platform for transparent and efficient trading of these billets. Traders, steel mills, and end-users can access real-time market data, monitor price fluctuations, and execute trades to optimize their supply chain and mitigate risks. In conclusion, LME Steel Billets offer a wide range of options to meet the diverse needs of the steel industry. By understanding the differences in types and their applications, industry participants can make informed decisions and capitalize on the opportunities offered by the LME marketplace.

Understanding the different types of LME Steel Billets allows participants in the industry to choose the appropriate billet for their specific requirements. Factors such as chemical composition, mechanical properties, and intended use play a significant role in determining the suitability of a particular billet type. The LME provides a centralized platform for transparent and efficient trading of these billets. Traders, steel mills, and end-users can access real-time market data, monitor price fluctuations, and execute trades to optimize their supply chain and mitigate risks. In conclusion, LME Steel Billets offer a wide range of options to meet the diverse needs of the steel industry. By understanding the differences in types and their applications, industry participants can make informed decisions and capitalize on the opportunities offered by the LME marketplace.

Your comment submitted.