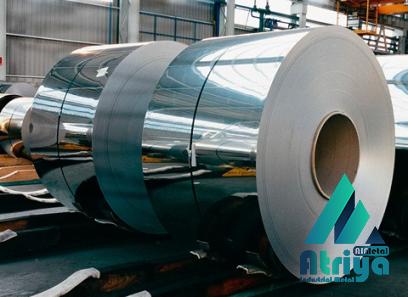

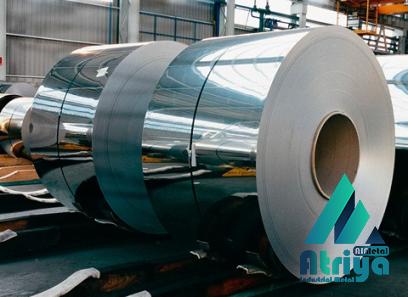

A Reliable Choice for Industries Introduction: In the world of steel manufacturing, cold rolled coil steel has gained significant recognition as a premium and versatile product. Renowned for its superior quality, exceptional flatness, and precise dimensions, cold rolled coil steel has emerged as a favored choice among various industries. This article aims to shed light on the remarkable properties and numerous applications that have made cold rolled coil steel an indispensable material in modern manufacturing. Unraveling the Process: Cold rolled coil steel is manufactured through a complex and meticulous process that involves multiple stages. The journey begins with hot rolled coils, which are first pickled and descaled to remove impurities, creating a clean surface. Subsequently, these coils are then passed through a series of cold reduction mills, where they are subjected to compressive forces. This process results in a significant reduction in thickness, enhancing the material’s strength and hardness. Superior Quality: The cold rolling process imparts several desirable characteristics to the steel, making it highly sought after.

.

One notable attribute is the impeccable flatness achieved through the precise rolling conditions. This flatness not only enhances the aesthetic appearance of finished products but also facilitates further processing, such as cutting and bending. Additionally, the process eliminates surface imperfections, ensuring a flawless finish and enabling efficient surface treatment applications, including galvanization and coating. Versatile Applications: Cold rolled coil steel finds extensive applications across numerous industries. One of its primary uses is in the automotive sector, where it is utilized for manufacturing various components, including body panels, chassis parts, and structural reinforcements. The excellent formability of cold rolled coil steel allows for intricate designs, while its strength and durability ensure the production of high-performance automotive parts. The construction industry also relies heavily on cold rolled coil steel.

One notable attribute is the impeccable flatness achieved through the precise rolling conditions. This flatness not only enhances the aesthetic appearance of finished products but also facilitates further processing, such as cutting and bending. Additionally, the process eliminates surface imperfections, ensuring a flawless finish and enabling efficient surface treatment applications, including galvanization and coating. Versatile Applications: Cold rolled coil steel finds extensive applications across numerous industries. One of its primary uses is in the automotive sector, where it is utilized for manufacturing various components, including body panels, chassis parts, and structural reinforcements. The excellent formability of cold rolled coil steel allows for intricate designs, while its strength and durability ensure the production of high-performance automotive parts. The construction industry also relies heavily on cold rolled coil steel.

..

Its exceptional strength and dimensional accuracy make it ideal for manufacturing steel frames, roofing, and cladding materials, as well as HVAC systems. Moreover, this versatile material is extensively employed in the electrical and electronics sector for manufacturing appliances, cables, and wiring. Advantages for Manufacturers and End-Users: Cold rolled coil steel offers several advantages that cater to the requirements of manufacturers and end-users alike. For manufacturers, the precise thickness and width tolerances of cold rolled coil steel reduce material waste and enable cost-effective production. Furthermore, its consistent mechanical properties ensure predictable and reliable performance. End-users benefit from the exceptional surface quality and improved aesthetics of products made from cold rolled coil steel.

Its exceptional strength and dimensional accuracy make it ideal for manufacturing steel frames, roofing, and cladding materials, as well as HVAC systems. Moreover, this versatile material is extensively employed in the electrical and electronics sector for manufacturing appliances, cables, and wiring. Advantages for Manufacturers and End-Users: Cold rolled coil steel offers several advantages that cater to the requirements of manufacturers and end-users alike. For manufacturers, the precise thickness and width tolerances of cold rolled coil steel reduce material waste and enable cost-effective production. Furthermore, its consistent mechanical properties ensure predictable and reliable performance. End-users benefit from the exceptional surface quality and improved aesthetics of products made from cold rolled coil steel.

…

Whether it is a consumer appliance, automotive part, or structural component, the smooth and uniform finish achieved by this material enhances the overall appeal and longevity of the final product. Conclusion: Cold rolled coil steel has become an essential material in various industries due to its exceptional quality and versatility. The rigorous manufacturing process ensures impeccable flatness, freedom from surface imperfections, and enhanced strength, making it an ideal choice for numerous applications. Whether it is used in automotive manufacturing, construction, or electrical components, cold rolled coil steel offers numerous advantages for manufacturers and end-users alike. As industries continue to evolve, cold rolled coil steel is poised to remain a steadfast and reliable choice for the challenges of modern manufacturing.

Whether it is a consumer appliance, automotive part, or structural component, the smooth and uniform finish achieved by this material enhances the overall appeal and longevity of the final product. Conclusion: Cold rolled coil steel has become an essential material in various industries due to its exceptional quality and versatility. The rigorous manufacturing process ensures impeccable flatness, freedom from surface imperfections, and enhanced strength, making it an ideal choice for numerous applications. Whether it is used in automotive manufacturing, construction, or electrical components, cold rolled coil steel offers numerous advantages for manufacturers and end-users alike. As industries continue to evolve, cold rolled coil steel is poised to remain a steadfast and reliable choice for the challenges of modern manufacturing.

Your comment submitted.