A Guide to Achieve Precision and Durability Stainless steel has become a popular choice in various industries due to its outstanding properties like corrosion resistance, strength, and aesthetic appeal. However, when it comes to bending stainless steel sheet, it requires specialized techniques and expertise to achieve the desired results. In this article, we will explore the process of bending stainless steel sheet, its applications, and the benefits it offers. 1. Understanding the Types of Stainless Steel Sheet: Stainless steel sheets are available in different grades, each with its unique characteristics. The most commonly used grades for bending are 304 and 316 stainless steel sheets. While 304 stainless steel is more affordable, 316 stainless steel offers enhanced corrosion resistance, making it suitable for applications where it comes into contact with harsh chemicals or environments. 2. Tools and Equipment for Bending: To bend stainless steel sheet effectively, several tools and equipment are required, including a press brake machine, die sets, clamps, and gauges. The press brake machine is essential for precision bending, allowing for accurate angles and dimensions.

.

It is crucial to ensure that all tools and equipment are properly maintained and calibrated for optimal performance. 3. Preparing Stainless Steel Sheets for Bending: Before beginning the bending process, the stainless steel sheets need to be properly prepared. Firstly, the sheets must be clean and free from any dirt, grease, or oils that may hinder the bending process. Additionally, the sheets should be flat and smooth, avoiding any surface imperfections that may lead to cracks or distortions during bending. 4. Choosing the Right Bending Technique: Several bending techniques can be utilized for bending stainless steel sheets, including air bending, bottoming, and coining. The choice of technique depends on the desired angle, bend radius, and the end application of the bent sheet. Understanding the limitations and advantages of each technique is crucial for achieving precise and consistent bends.

It is crucial to ensure that all tools and equipment are properly maintained and calibrated for optimal performance. 3. Preparing Stainless Steel Sheets for Bending: Before beginning the bending process, the stainless steel sheets need to be properly prepared. Firstly, the sheets must be clean and free from any dirt, grease, or oils that may hinder the bending process. Additionally, the sheets should be flat and smooth, avoiding any surface imperfections that may lead to cracks or distortions during bending. 4. Choosing the Right Bending Technique: Several bending techniques can be utilized for bending stainless steel sheets, including air bending, bottoming, and coining. The choice of technique depends on the desired angle, bend radius, and the end application of the bent sheet. Understanding the limitations and advantages of each technique is crucial for achieving precise and consistent bends.

..

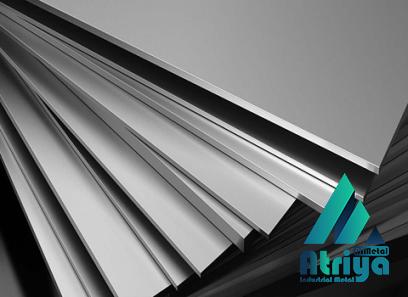

5. Achieving Precision and Durability: One of the significant challenges in bending stainless steel sheets is maintaining their structural integrity while achieving the desired bend radius. Stainless steel is known for its spring-back effect, which means that after bending, it tends to return to its original shape. To combat this, skilled operators control the bend angle and utilize proper tooling techniques to maintain the desired shape. This ensures precision and durability in the bent stainless steel sheets. 6. Applications of Bent Stainless Steel Sheets: Bent stainless steel sheets find applications in various industries, including architecture, automotive, aerospace, and medical. In architecture, stainless steel sheets are often bent to create decorative elements, such as handrails, signage, and façade panels. In the automotive and aerospace industries, bent stainless steel sheets are used for structural components and exhaust systems due to their corrosion resistance and high strength. Additionally, the medical industry utilizes bent stainless steel sheets for various equipment and instruments.

5. Achieving Precision and Durability: One of the significant challenges in bending stainless steel sheets is maintaining their structural integrity while achieving the desired bend radius. Stainless steel is known for its spring-back effect, which means that after bending, it tends to return to its original shape. To combat this, skilled operators control the bend angle and utilize proper tooling techniques to maintain the desired shape. This ensures precision and durability in the bent stainless steel sheets. 6. Applications of Bent Stainless Steel Sheets: Bent stainless steel sheets find applications in various industries, including architecture, automotive, aerospace, and medical. In architecture, stainless steel sheets are often bent to create decorative elements, such as handrails, signage, and façade panels. In the automotive and aerospace industries, bent stainless steel sheets are used for structural components and exhaust systems due to their corrosion resistance and high strength. Additionally, the medical industry utilizes bent stainless steel sheets for various equipment and instruments.

…

7. Advantages of Bending Stainless Steel Sheets: Bending stainless steel sheets offers several advantages. Firstly, it allows for the creation of complex shapes and designs, enhancing the aesthetics of the end product. Secondly, stainless steel’s corrosion resistance remains intact even after bending, making it suitable for applications exposed to harsh environments. Lastly, the durability and strength of stainless steel ensure that the bent sheets can withstand mechanical stresses and provide long-lasting performance. In conclusion, bending stainless steel sheets requires skill, precision, and excellent knowledge of the material properties. With the right tools, techniques, and expertise, stainless steel can be bent to achieve precise angles and dimensions while maintaining its structural integrity. The versatility and durability of bent stainless steel sheets make them a popular choice in various industries, offering an array of applications that benefit from its outstanding properties.

7. Advantages of Bending Stainless Steel Sheets: Bending stainless steel sheets offers several advantages. Firstly, it allows for the creation of complex shapes and designs, enhancing the aesthetics of the end product. Secondly, stainless steel’s corrosion resistance remains intact even after bending, making it suitable for applications exposed to harsh environments. Lastly, the durability and strength of stainless steel ensure that the bent sheets can withstand mechanical stresses and provide long-lasting performance. In conclusion, bending stainless steel sheets requires skill, precision, and excellent knowledge of the material properties. With the right tools, techniques, and expertise, stainless steel can be bent to achieve precise angles and dimensions while maintaining its structural integrity. The versatility and durability of bent stainless steel sheets make them a popular choice in various industries, offering an array of applications that benefit from its outstanding properties.

Your comment submitted.