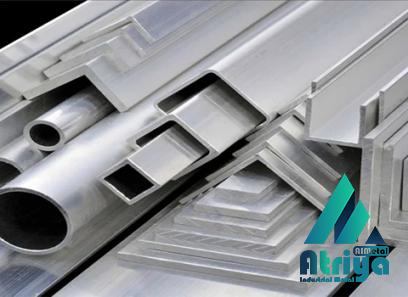

The Versatile Material Revolutionizing Industries Aluminium alloy is a remarkable substance that has revolutionized various industries. With its unique properties and versatile nature, it has become an integral part of modern manufacturing processes. This lightweight material offers a multitude of advantages, making it an ideal choice for a wide range of applications. One of the key reasons behind the popularity of aluminium alloy is its exceptional strength-to-weight ratio. This attribute allows manufacturers to reduce the weight of components and structures while maintaining their strength and integrity. Therefore, industries such as aerospace, automotive, and construction have increasingly adopted this alloy to enhance fuel efficiency, increase payload capacity, and improve overall performance.

.

In the aerospace industry, aluminium alloy is widely used in the production of aircraft and spacecraft components. Its low density and high corrosion resistance make it an excellent choice for constructing aircraft fuselages, wings, and other structural elements. Moreover, aluminium alloy’s ability to withstand extreme temperatures and harsh environments further solidifies its preference in the aerospace field. The automotive industry has also embraced aluminium alloy due to its potential to reduce vehicle weight, resulting in improved fuel efficiency and reduced emissions. The alloy’s malleability enables the creation of complex shapes and designs, making it ideal for manufacturing engine parts and body panels.

In the aerospace industry, aluminium alloy is widely used in the production of aircraft and spacecraft components. Its low density and high corrosion resistance make it an excellent choice for constructing aircraft fuselages, wings, and other structural elements. Moreover, aluminium alloy’s ability to withstand extreme temperatures and harsh environments further solidifies its preference in the aerospace field. The automotive industry has also embraced aluminium alloy due to its potential to reduce vehicle weight, resulting in improved fuel efficiency and reduced emissions. The alloy’s malleability enables the creation of complex shapes and designs, making it ideal for manufacturing engine parts and body panels.

..

Additionally, its excellent heat dissipation properties aid in cooling systems, enhancing engine performance and longevity. In the construction sector, aluminium alloy’s lightness and durability make it an ideal material for builders and architects. It is commonly used in the construction of skyscrapers, bridges, windows, and doors. The alloy’s resistance to corrosion ensures structures withstand harsh weather conditions, while its reflective properties make it an efficient choice for energy-saving installations. Beyond aerospace, automotive, and construction, aluminium alloy finds applications in various industries such as packaging, electronics, and consumer goods. Its excellent thermal conductivity and electrical conductivity make it a preferred material for heat sinks, electrical connectors, and electronic enclosures. Additionally, its non-toxic nature and ability to be recycled without the loss of properties make it an environmentally friendly choice for packaging materials.

Additionally, its excellent heat dissipation properties aid in cooling systems, enhancing engine performance and longevity. In the construction sector, aluminium alloy’s lightness and durability make it an ideal material for builders and architects. It is commonly used in the construction of skyscrapers, bridges, windows, and doors. The alloy’s resistance to corrosion ensures structures withstand harsh weather conditions, while its reflective properties make it an efficient choice for energy-saving installations. Beyond aerospace, automotive, and construction, aluminium alloy finds applications in various industries such as packaging, electronics, and consumer goods. Its excellent thermal conductivity and electrical conductivity make it a preferred material for heat sinks, electrical connectors, and electronic enclosures. Additionally, its non-toxic nature and ability to be recycled without the loss of properties make it an environmentally friendly choice for packaging materials.

…

Although aluminium alloy offers numerous advantages, it is not without challenges. Its high cost compared to other materials, such as steel, can pose a hurdle for its widespread adoption. However, advancements in manufacturing technologies and processes have been driving down costs, making aluminium alloy increasingly competitive. In conclusion, aluminium alloy’s unique properties and versatility have propelled it to the forefront of modern industries. Its lightweight nature, exceptional strength, corrosion resistance, and electrical conductivity have made it an indispensable material in aerospace, automotive, construction, and other sectors. As technology continues to evolve and manufacturing processes become more efficient, aluminium alloy is poised to play an even more significant role in shaping the industries of the future.

Although aluminium alloy offers numerous advantages, it is not without challenges. Its high cost compared to other materials, such as steel, can pose a hurdle for its widespread adoption. However, advancements in manufacturing technologies and processes have been driving down costs, making aluminium alloy increasingly competitive. In conclusion, aluminium alloy’s unique properties and versatility have propelled it to the forefront of modern industries. Its lightweight nature, exceptional strength, corrosion resistance, and electrical conductivity have made it an indispensable material in aerospace, automotive, construction, and other sectors. As technology continues to evolve and manufacturing processes become more efficient, aluminium alloy is poised to play an even more significant role in shaping the industries of the future.

Your comment submitted.