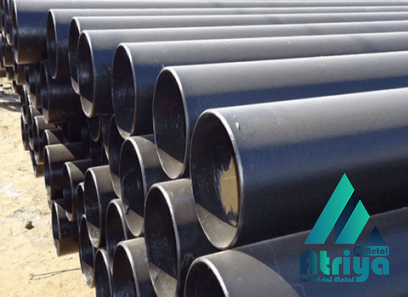

Understanding the Differences for Your Business When it comes to steel, businesses have a wide range of options to choose from. Two common types include medium carbon steel and mild steel. While both materials are widely used across industries, understanding their differences is crucial for making informed decisions for your business. In this article, we will explore the distinctions between medium carbon steel and mild steel, and how they can impact your operations. First, let’s take a closer look at mild steel. Mild steel, also known as low carbon steel, is the most commonly used form of steel due to its affordability and versatility. It contains a low percentage of carbon, typically ranging from 0.05% to 0.25%. The low carbon content makes mild steel more ductile and easy to work with. It can be easily welded, shaped, and formed into various products, from construction materials to automotive parts. On the other hand, medium carbon steel contains a higher percentage of carbon, typically ranging from 0.25% to 0.60%.

.

This higher carbon content provides medium carbon steel with increased strength and hardness compared to mild steel. It is known for its robustness and ability to withstand heavy loads, making it a popular choice in applications that require enhanced durability, such as machinery components, tools, and industrial equipment. One notable difference between medium carbon steel and mild steel lies in their respective strengths. Due to its higher carbon content, medium carbon steel exhibits greater tensile and yield strength compared to mild steel. This added strength makes it more suitable for applications that demand higher toughness and resistance to wear and abrasion. However, the increased strength of medium carbon steel comes at a cost.

This higher carbon content provides medium carbon steel with increased strength and hardness compared to mild steel. It is known for its robustness and ability to withstand heavy loads, making it a popular choice in applications that require enhanced durability, such as machinery components, tools, and industrial equipment. One notable difference between medium carbon steel and mild steel lies in their respective strengths. Due to its higher carbon content, medium carbon steel exhibits greater tensile and yield strength compared to mild steel. This added strength makes it more suitable for applications that demand higher toughness and resistance to wear and abrasion. However, the increased strength of medium carbon steel comes at a cost.

..

Its higher carbon content makes it more brittle and less malleable than mild steel. This means that medium carbon steel is less forgiving when subjected to extreme bending or shaping processes. In contrast, mild steel’s low carbon content provides it with excellent ductility, allowing for easy deformation without compromising its structural integrity. Furthermore, the higher carbon content in medium carbon steel also makes it more susceptible to corrosion compared to mild steel. While both types of steel can be vulnerable to rusting, mild steel tends to have better resistance to corrosion due to its lower carbon composition. This is especially important in applications exposed to environmental elements, such as outdoor structures or marine equipment.

Its higher carbon content makes it more brittle and less malleable than mild steel. This means that medium carbon steel is less forgiving when subjected to extreme bending or shaping processes. In contrast, mild steel’s low carbon content provides it with excellent ductility, allowing for easy deformation without compromising its structural integrity. Furthermore, the higher carbon content in medium carbon steel also makes it more susceptible to corrosion compared to mild steel. While both types of steel can be vulnerable to rusting, mild steel tends to have better resistance to corrosion due to its lower carbon composition. This is especially important in applications exposed to environmental elements, such as outdoor structures or marine equipment.

…

In summary, medium carbon steel and mild steel offer distinct advantages and disadvantages, depending on the specific requirements of your business. If your application demands increased strength, hardness, and resistance to wear, medium carbon steel may be the preferable choice. However, if flexibility, ease of fabrication, and corrosion resistance are your priorities, mild steel may be a more suitable option. Understanding the differences between medium carbon steel and mild steel allows you to make informed decisions and select the right material for your business needs. Consider factors such as strength, ductility, malleability, and corrosion resistance when evaluating the applications of these two types of steel. By choosing the appropriate steel for your projects, you can ensure the longevity, durability, and performance of your products while maintaining cost-effectiveness.

In summary, medium carbon steel and mild steel offer distinct advantages and disadvantages, depending on the specific requirements of your business. If your application demands increased strength, hardness, and resistance to wear, medium carbon steel may be the preferable choice. However, if flexibility, ease of fabrication, and corrosion resistance are your priorities, mild steel may be a more suitable option. Understanding the differences between medium carbon steel and mild steel allows you to make informed decisions and select the right material for your business needs. Consider factors such as strength, ductility, malleability, and corrosion resistance when evaluating the applications of these two types of steel. By choosing the appropriate steel for your projects, you can ensure the longevity, durability, and performance of your products while maintaining cost-effectiveness.

Your comment submitted.