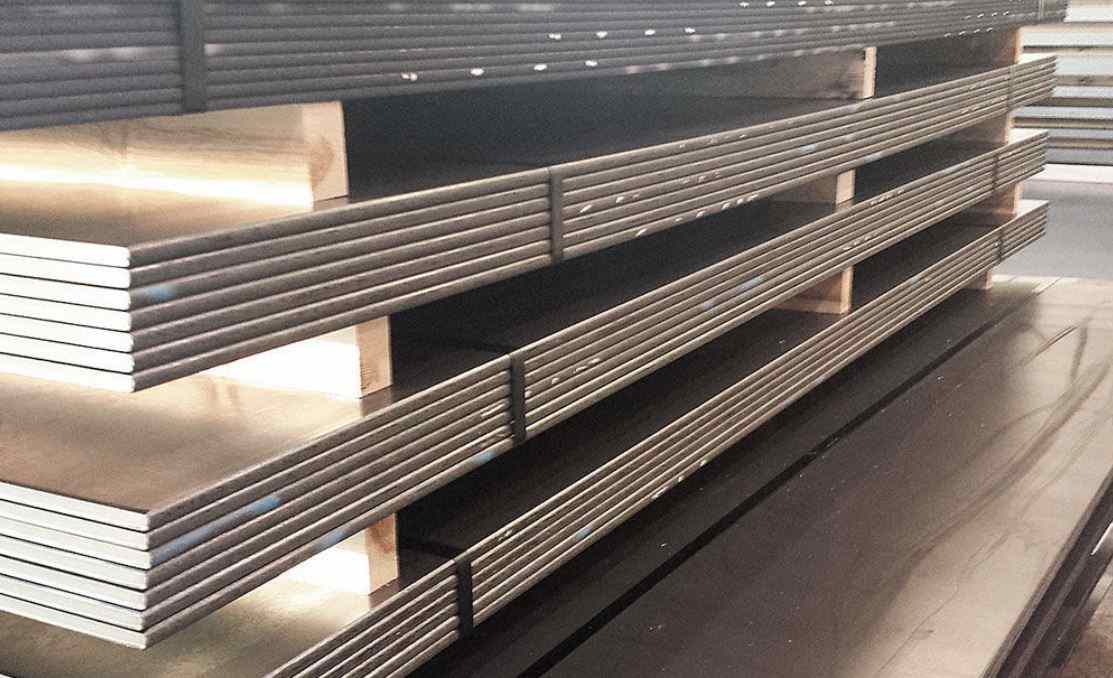

Introducing 3mm black steel + the best purchase price

Based on data provided by the World Steel Association analysis department, the World Steel Association estimated that the total amount of steel produced globally in 2019 was close to 1869

9 million tonnes

When compared to the production in the year 1999, this results in a more than thrice rise in output, and when compared to the production in the year 2018, it results in a more than 3

4% increase in output

There is every reason to believe that the demand for steel will continue to increase globally in the near future

This is excellent news for the steel sector

This is very promising news for the steel industry

It applies to a wide range of industries, including the manufacturing and construction sectors, to name just two examples of those kinds of companies

It is a great option for manufacturing of any kind because it is economical and durable throughout the course of the production cycle as well as throughout the entire product’s lifecycle

It is a great option for use because of this

Precision sheet metal fabrication is one of the most frequently utilized production processes today

Production of sheet metal is essential to the many technological advancements we’ve seen in fields including consumer electronics, aerospace, electronics, medical, transportation, and more

In truth, almost every industry uses sheet metal fabrication

black steel sheet 12×12 24 x 36 9 x 12

Black steel sheet metals are characterized according to their thickness, length, and width so that their characteristics may be understood for specialized applications

Prices vary according to various sizes

When these different dimensions of black steel sheets were being manufactured, there was a particular use in planning for each and every one of these diverse applications for each and every one of these different sizes

The following are the dimensions of the object, given in inches: 12×12 24 x 36 9 x 12 accordingly

Sheets made of mild steel are put to extensive use in the production of motor cars, household appliances, building projects, and other types of general metal fabrication

Although mild steel sheet is a cost-effective material, it does typically need to have a protective and decorative finish applied to it in order to avoid corrosion and add aesthetic value

Sheets made of mild steel can undergo a variety of finishing processes

It is possible to paint sheets made of mild steel, and there are hundreds of specifications that cover this technique and the materials involved

Powder coating and liquid coating are the two most common forms of this technique

Sheets of mild steel can have a plastic coating applied to them, such as nylon, polythene, or PVC, for example

The top surfaces of steel sheets made of mild steel can be galvanized through a process called galvanizing, which includes alloying the steel sheets with zinc that has been melted

Electroplating can also be used to add finishes such as chrome, nickel, cadmium, and tin to a sheet made of mild steel

black steel sheet 2400 x 1200

To make it easier to understand the features of black steel sheet metals for specialized applications, these sheet metals are classified based on their thickness, length, and width

Prices change based on different sizes

There was a specific use in planning for each and every one of these numerous applications for each and every one of these various sizes when these various dimensions of black steel sheets were being created

The item’s measurements are as follows, in inches: 2400 x 1200, correspondingly

The sheet metal production process has evolved and improved through time as a result of the substantial demand and expanding uses across numerous sectors

Because it uses so many different processes, sheet metal fabrication has evolved into a field of art that demands the highest level of workmanship

Precision sheet metal fabrication is one of the most frequently utilized production processes today

Production of sheet metal is essential to the many technological advancements we’ve seen in fields including consumer electronics, aerospace, electronics, medical, transportation, and more

In truth, almost every industry uses sheet metal fabrication

Supplies and Techniques utilized while creating sheet metal Sheet metal fabrication processes and methods include cutting, forging, rolling, bending, assembling, engineering, welding, braking, powder coating, stamping, turret, and laser automation, riveting, punching, sub-contract manufacturing, prototype, machine design, and technical drawing

The processes used to produce sheet metal have very limited tolerance for error and require highly skilled employees

Manufacturing relies heavily on the manufacture of sheet metal, which is utilized in everything from large-scale structural projects and construction equipment to sophisticated telephones and electronics

Sheet metal is made from a wide variety of materials

Strength, conductivity, hardness, flexibility, and corrosion resistance are all qualities that are usually sought in metals used to make sheet metal

black steel sheet 4×4 4×8 6×6

A solid understanding of steel sheet metal theory is essential for successful welding and engineering

Every welder should have a firm understanding of this topic because sheet metal makes up the largest portion of metalworking processes

Any piece of metal with a width between 0

5 and 6mm is considered sheet metal

The thickness of sheet metal is determined by this width

Plate metal is defined as having a thickness greater than 6mm, while foil metal is defined as having a thickness less than 0

5mm

What Does Sheet Metal Gauge Mean? The term “gauge” is frequently used to describe metal thickness

While having the same thickness, some metals may have a different gauge

A 6mm aluminum sheet, for instance, has a different gauge than a galvanized steel sheet of a similar size

In North America, people often use the word gauge

Most engineers use the gauge to describe the thickness of metal

A unit for measuring diameter is called a gauge (Ga

)

It shows the relationship between metal thickness and weight per square foot

In both cases, a small gauge indicates a larger diameter and, consequently, a larger thickness

Metals of equal thickness that are both ferrous and non-ferrous have a different gauge

But there are gauges for various metals on the sheet metal gauge chart

While aluminum, brass, and copper of the same gauge have a thickness of 2

88mm, standard steel of gauge 10 has a thickness of 3

416

Additionally, standard 20 gauge steel is 0

912 mm thick, while its non-ferrous counterparts are 0

813 mm thick

black steel sheet 6×4 6×10 8×8

Steel sheet is one of the most commonly used materials in metalworking

It has been around for at least a thousand years but in a somewhat different form

Despite the fact that sheet metal can be found in a wide variety of applications, including industrial kitchens, automobiles, and roofs, the process of making sheet metal is very same throughout all of these applications

In the field of metalworking, it is common knowledge that the thickness of sheet metal can range anywhere from 0

006 to 0

25

Everything thicker than foil is termed plate, while everything thinner than plate is considered foil

However, despite the fact that the material may be referred to by a variety of names depending on its thickness, the process of fabrication is often the same for all of them

The transformation of a caterpillar into a butterfly is likely to be more fascinating to observe than the process of making sheet metal, which may not be as attractive to watch

However, it is helpful to understand each stage from the perspective of purchasing and engineering

Engineers are the ones in charge of the design process, and they put in a lot of effort to make sure that the idea they put down on paper will result in a product that lives up to everyone’s standards

The design process begins with the creation of blueprints, continues with the creation of rough drawings, and then concludes with the creation of final drawings

It is of the utmost importance that the design is precise since, if it is not, the final product might not function properly in the actual world

black steel sheet 8×4 price

Sheet metal is a term that refers to several types of metal that have been reduced in thickness and flattened through various industrial processes

Sheet metal, which can be formed and sculpted into a variety of different forms through bending and cutting, is one of the fundamental components of the metalworking industry

Extremely thin sheets are referred to as foil and leaf, whilst sections thicker than 6 mm (0

25 in) are referred to as plate, which includes structural steel plate

There are numerous varieties of thicknesses

Both flat sheet metal and coiled strips are easily accessible

A roll slitter cuts a continuous metal sheet into coils

The thickness of sheet metal is commonly specified in millimeters

In the US, sheet metal thickness is measured using a gauge, a non-linear metric

Thinner metal is produced by a higher gauge

The steel sheet is typically 30 to 7 gauge

Metals made of aluminum or copper have different gauges than metals composed of iron

Either copper thickness or ounces are used in the computation of copper per square foot

A consistent sheet metal thickness is preferred

Sheet metal can be made from a variety of metals, including aluminum, brass, copper, steel, tin, nickel, and titanium

Silver, gold, and platinum are significant sheet metals for aesthetic purposes (platinum sheet metal is also utilized as a catalyst)

The bodywork of automobiles, trucks, and lorries, as well as large appliances, airplane wings, tinplate for tin cans, and roofs for structures, are all made of sheet metal

Transformers and other electrical equipment use high-permeability materials such as laminated steel cores, iron sheet metal, and others

The metal sheet was once used to make cavalry plate armor

black steel sheet 8×4 weight

There is a correlation between the gauge and the weight of each individual sheet

In the United States, the standard unit for calculating weight is expressed as a ratio of pounds to square feet

The metric system uses kilograms per square meter as the unit of weight throughout much of the world, including Europe

“Black sheet” refers to the flat steels that are produced as a further step after casting-method products are rolled and then rolled again

The process of hot rolling is used to manufacture models made of mild steel

To put it another way, the steel is first heated to a temperature higher than the point at which it begins to crystallize

After that, the material is rolled using rollers that are parallel to one another

At this stage, the reduced complexity of the geometry of the heated steel offers a major advantage

Because of this feature, you will have the capacity to make goods that have the appropriate thickness and dimensions

At this juncture in the production of the black sheet, it is quite essential that there are no delays

What Is Hot Rolling? The steel is rolled at a very high temperature known as “hot rolling,” which must be higher than the steel’s recrystallization temperature of 920°C

These temperatures enable the steel to be easily shaped and molded into much greater sizes

Because there is less manufacturing process delay, HRC is often cheaper than cold-rolled steel

However, after the steel cools down, it has a propensity to somewhat contract, giving you less control over the final product’s size and shape

Therefore, applications, where precise forms and tolerances are not necessary, are those where hot-rolled steel is most frequently employed

Steel offers unrivaled tensile strength and construction support

Steel has superior strength and durability to wood and concrete

Steel is a common building material due to its many advantages

Clearspan, modular, and single-slope frames are all types of steel structures

Due to its simplicity and other advantages, steel has quickly surpassed other building materials

Steel construction is the best

Steel is robust and long-lasting

Due to its many advantages, steel is the ideal material for building support

Steel buildings require frames

Steel construction is preferred since it is quicker

Our goal is to deliver finished goods, semi-finished goods, and steel derivatives of the highest caliber